ALIENS Stasis Chamber!!!

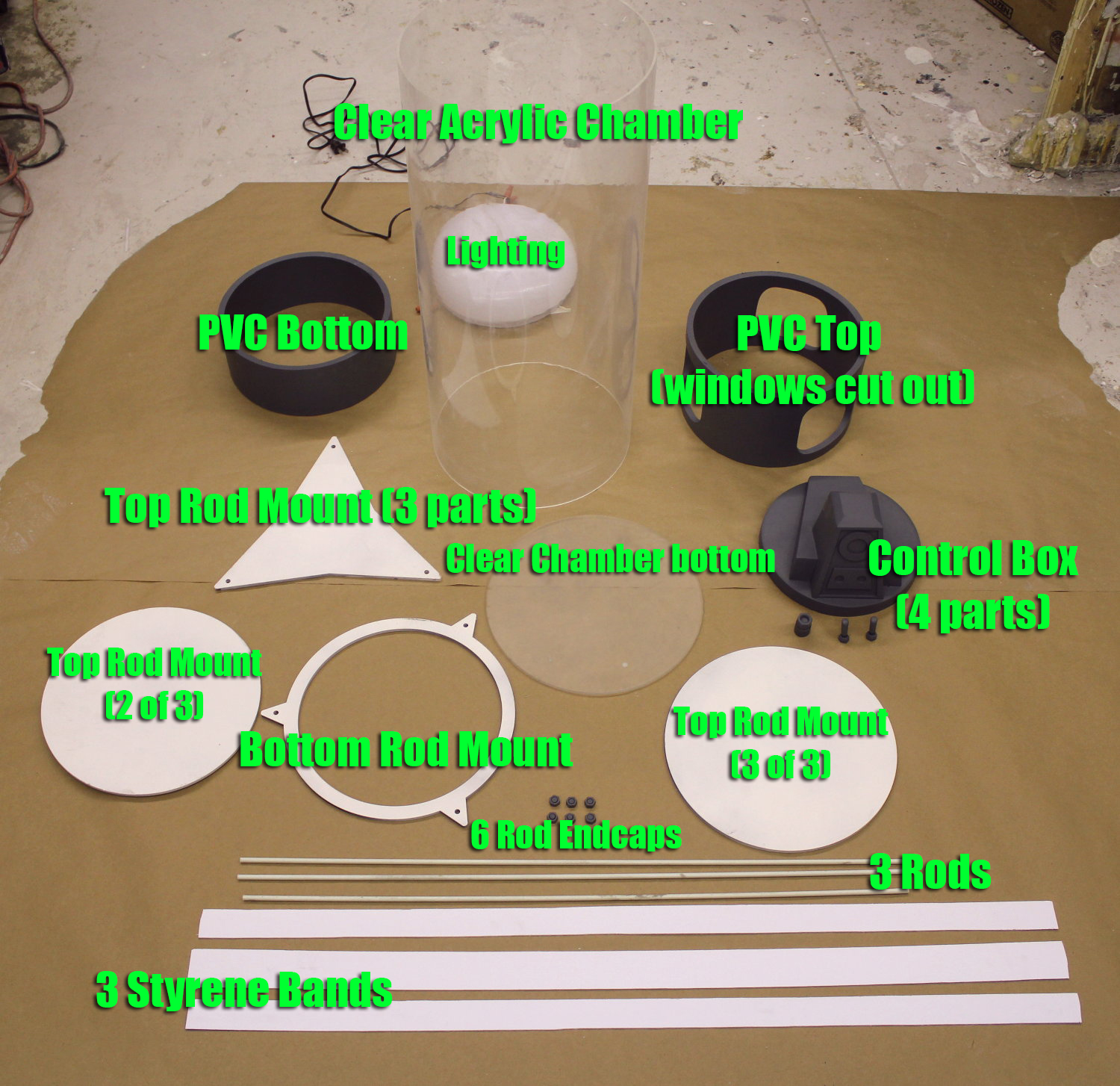

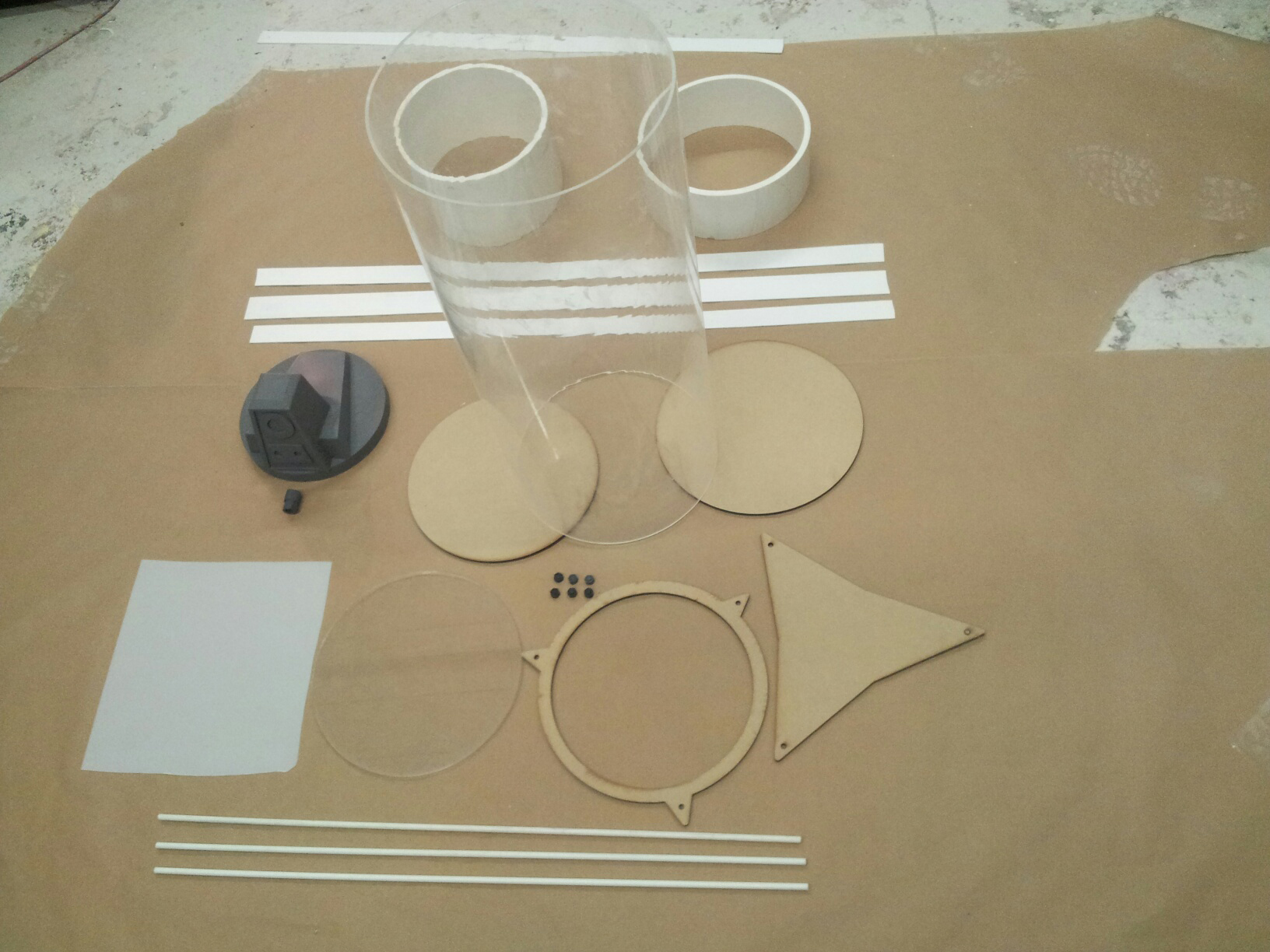

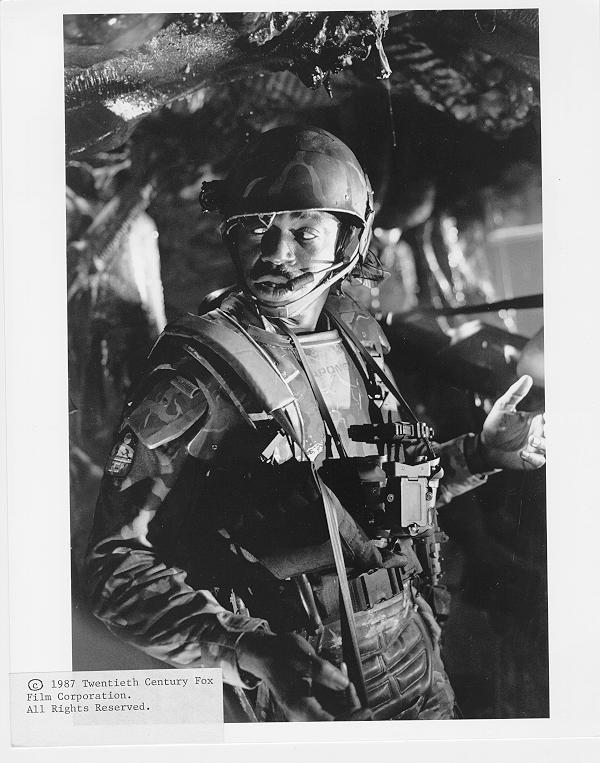

This replica truly is LIFESIZED. It utlizes a 12" O.D. cut to 31" clear acrylic tube. Each component is precision-machined and laser cut for accuracy.

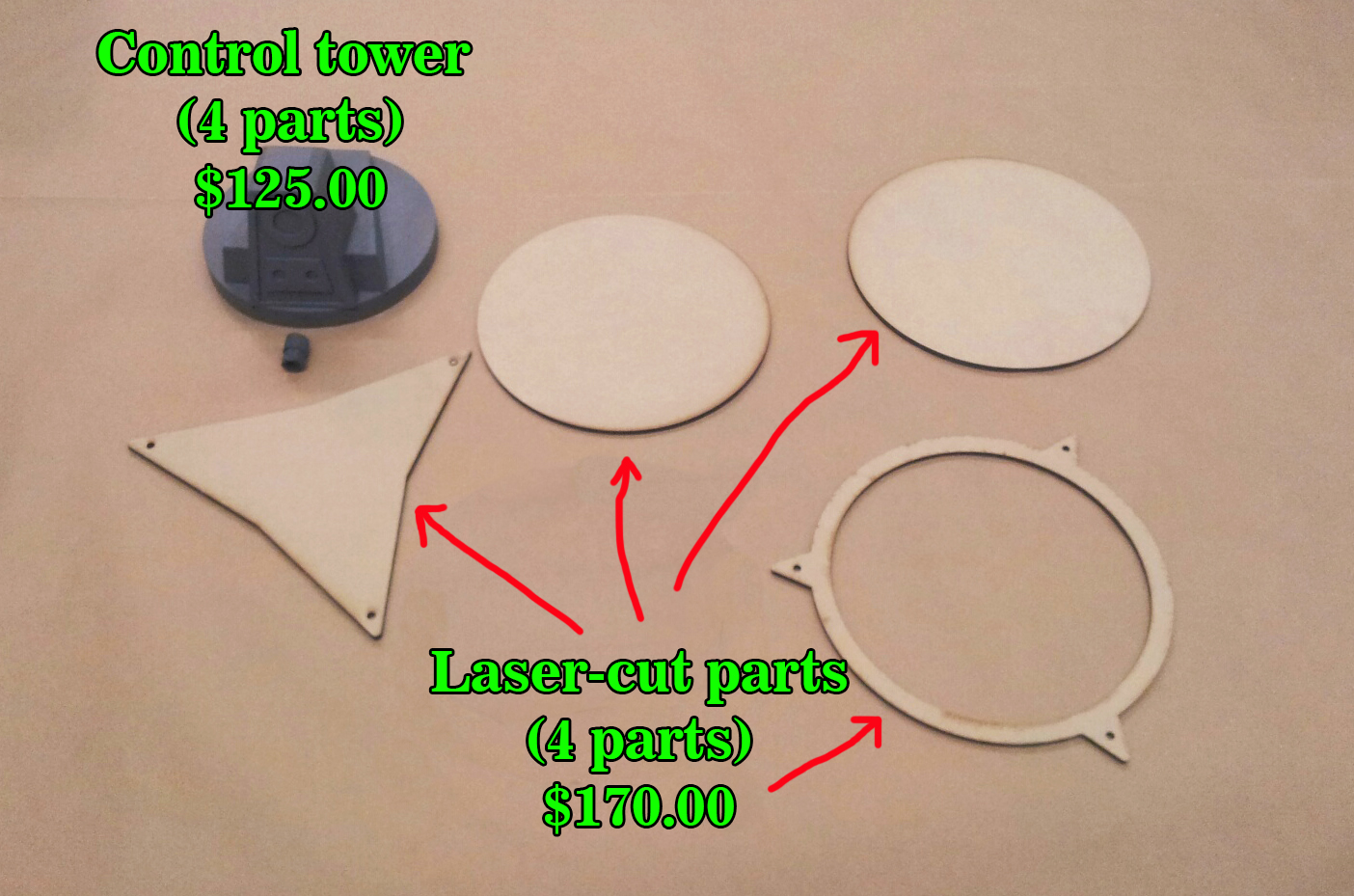

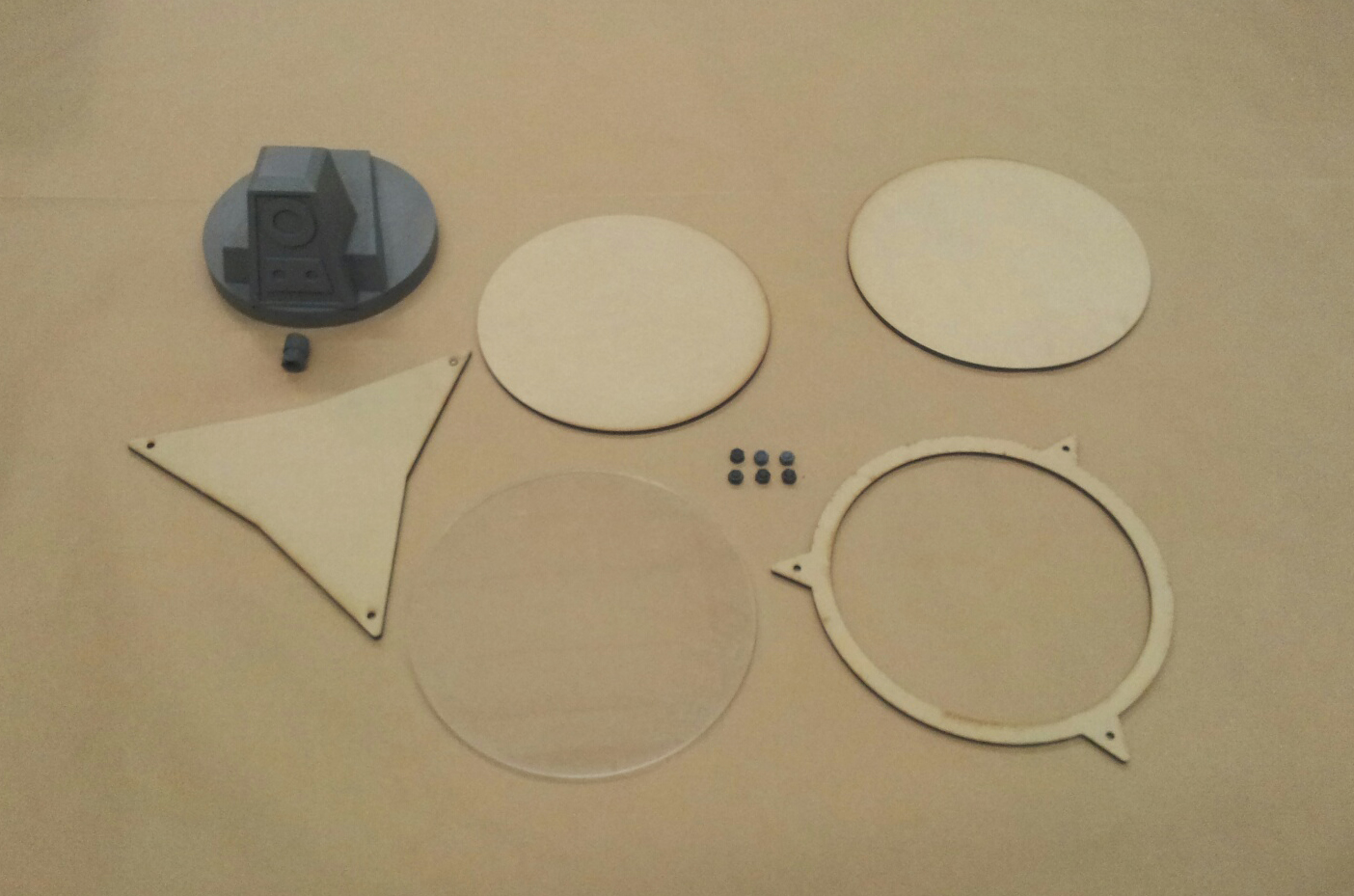

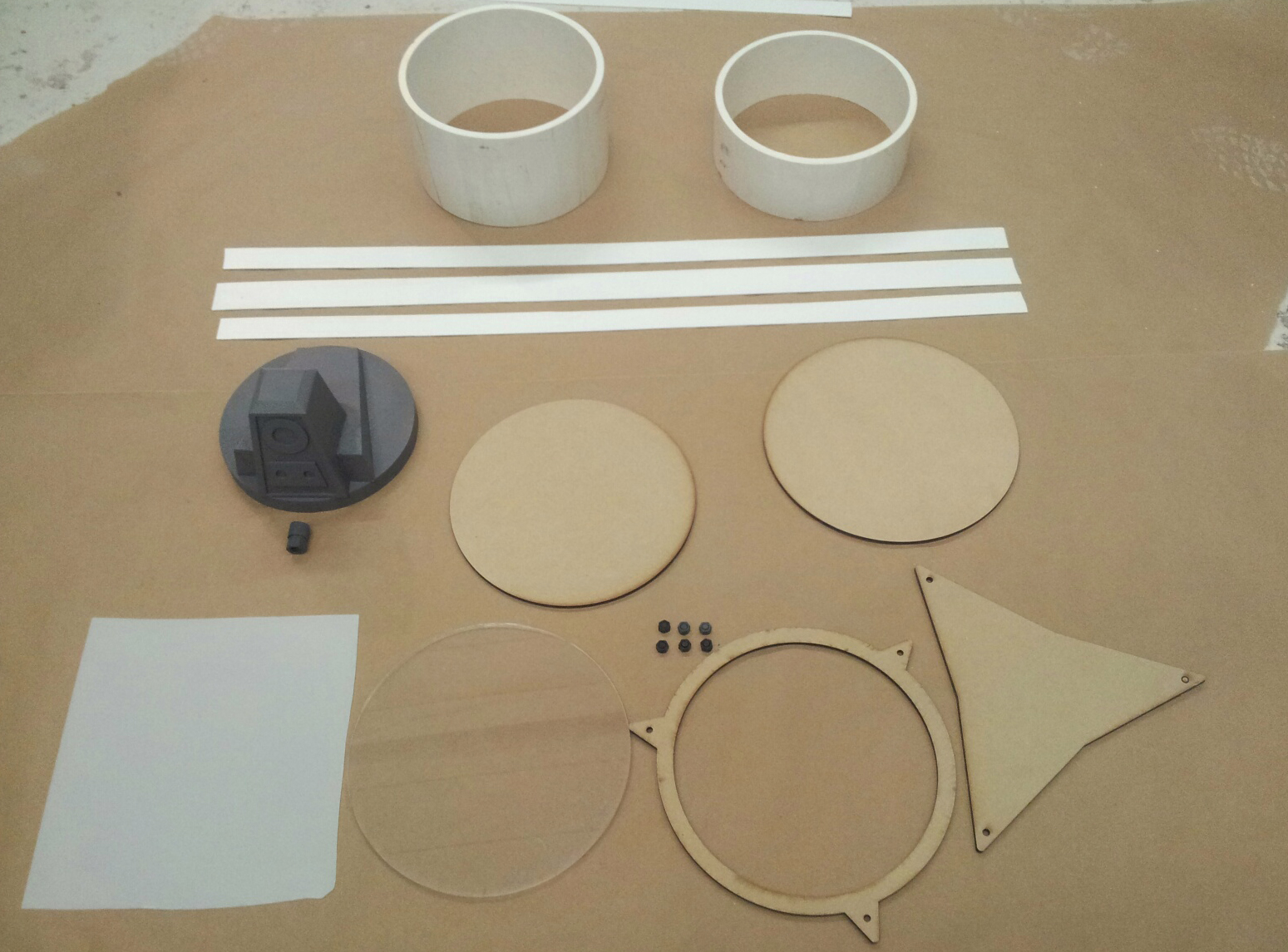

I currently offer the control box and CNC cut parts (composit wood). The rods and clear acrylic tube, etc... can all be found at your local plastics supply shop.

Online you can try: castplexusa.com

As of 2022, here is what I offer: (all other parts are found at your local plastics supplier shop). The large diameter PVC tube for the top and bottom can be found at lowes/home depot.

CLICK ME TO SEE A PHOTO GALLERY OF THIS MAGNIFICENT PHOTO GALLERY!!!

KIT PARTS

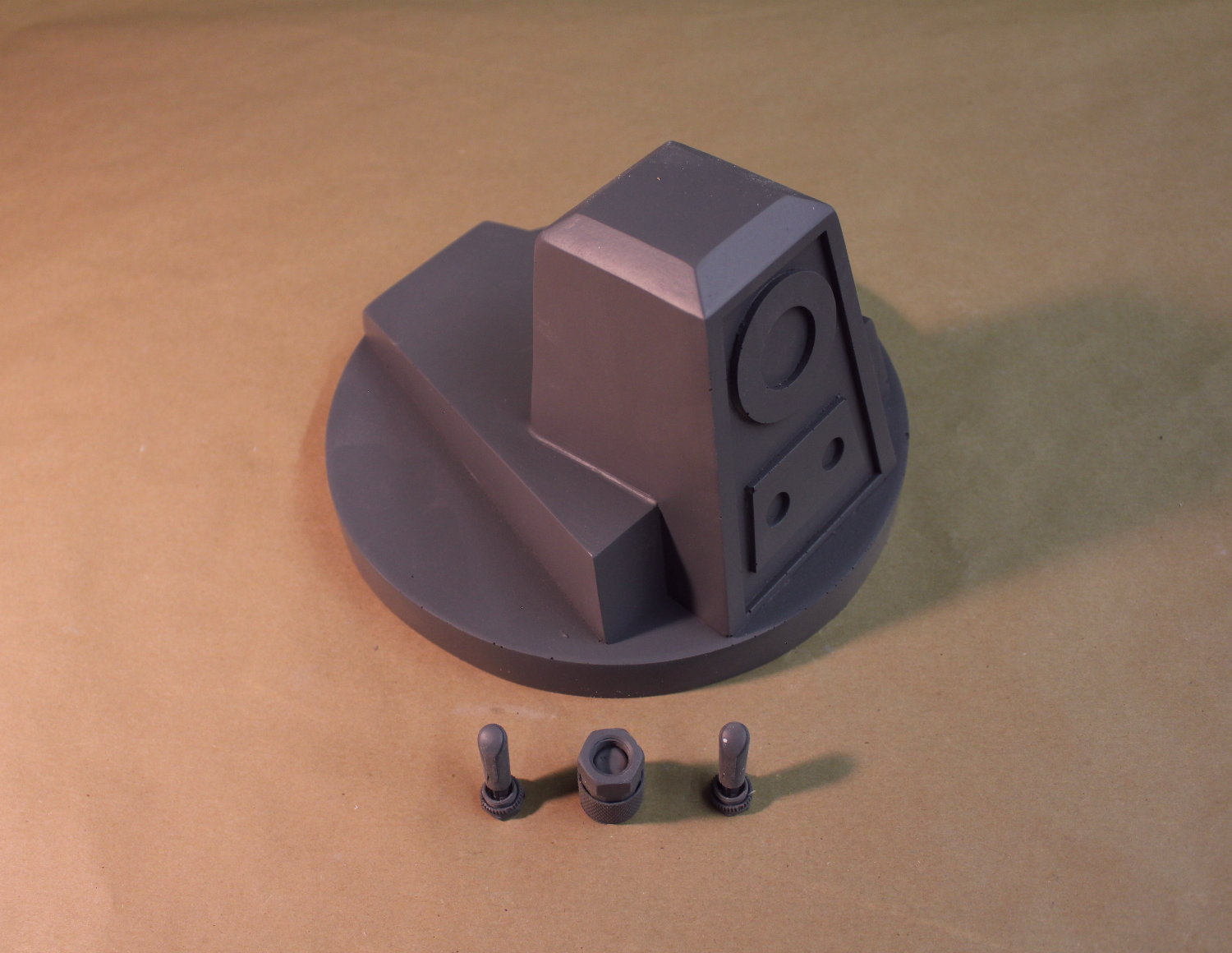

The CONTROL BOX by itself is: DIAMETER: 23.5 cm (9.25")

TALL: 15.9 cm (6.25")

______________________________________________________________

HOW IT WAS MADE:

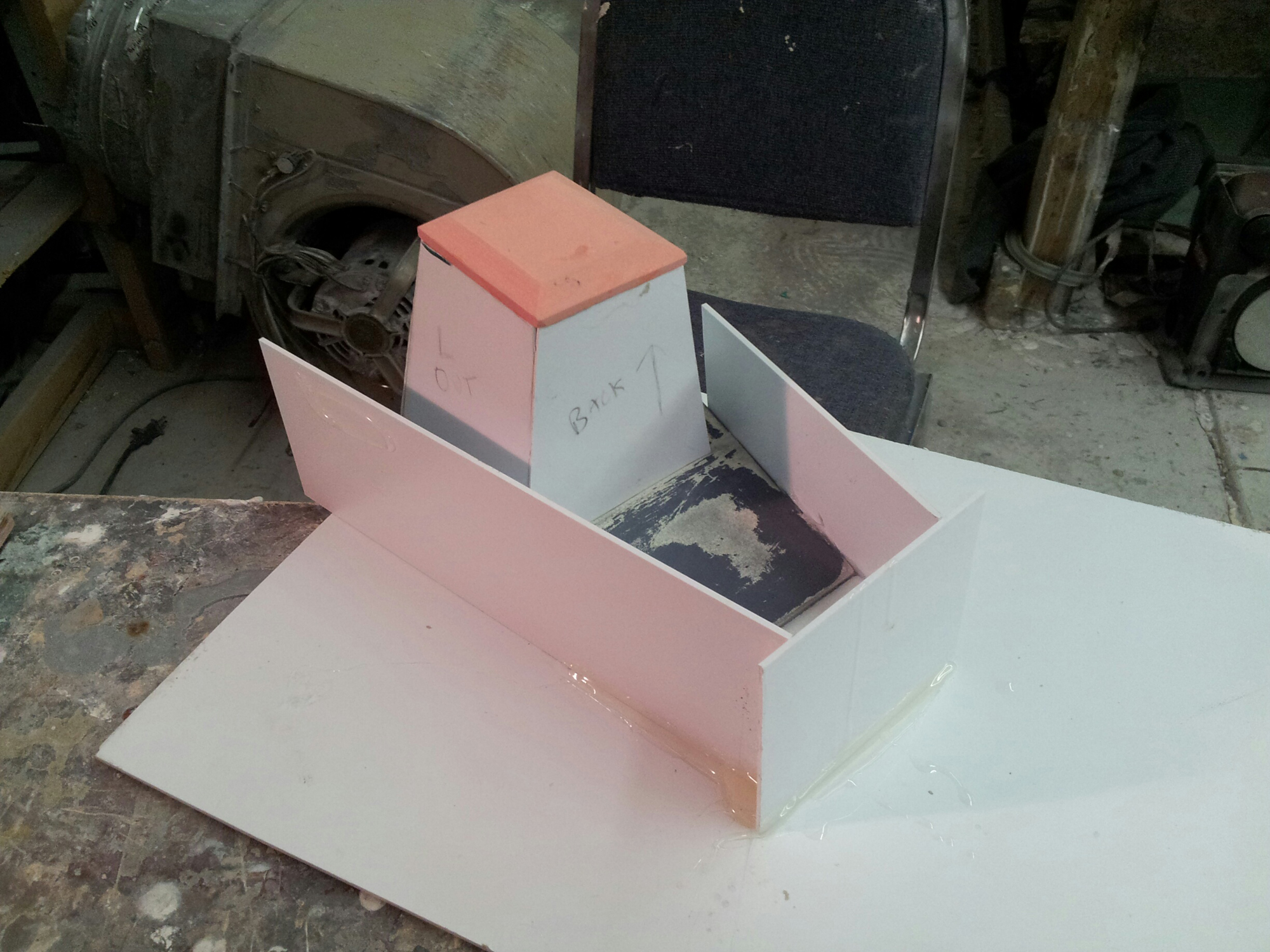

Scratch-building the CONTROL BOX:

Once the shapes were blocked out in styrene, I created CAD drawings of the faceplate and laser cut the layered panels in acrylc. These parts were carefully assembled into position.

Completed control box with switches and connection port.

Creating the Tube and Fittings.

Once I had the clear tube to work with, I went out scaling all the other parts and redesigning the fittings. CAD drawings were drawn up and the parts were machined in acrylic for test fittings.

At first I attempted to hand-cut the windows from the PVC tube at the top, but quickly realized I would have to make a custom CNC jig to do this properly. Here's the results:

At first I attempted to hand-cut the windows from the PVC tube at the top, but quickly realized I would have to make a custom CNC jig to do this properly. Here's the results:

I kept having to scale down the clear tube until I was satisfied with the proportions.

Just a little fine-tuning with some styrene and I was ready for the first finished assembly!

Assembling and painting THE FACEHUGGER!!

Visit the Colonial Marines!!

CLICK FOR BODY ARMOR INFORMATION (now thermal formed in .125 gauge ABS plastic).

Reader Comments (1)

Waiting for the tube tutorial