BLADE RUNNER VOIGHT KAMPFF MACHINE

Wednesday, November 1, 2017 at 7:46PM

Wednesday, November 1, 2017 at 7:46PM BLADE RUNNER VOIGHT KAMPFF MACHINE

BLADERUNNER was such an inspiration to me and was one of the films that encouraged me to become a filmmaker, animator and artist. While at UCLA film classes, I wrote my final on the cinematic virtues of BR. After all these years I finally decided to tackle a lifesize replica of the Voight Kampff machine seen in the film. Welcome to my VK project page!!

ATTENTION!: I CANNOT SHIP ITEMS OVERSEAS. THE BUYNOW BUTTONS ARE ONLY FOR BUYERS THAT HAVE A U.S. ADDRESS. PLEASE DO NOT USE THE BUYNOW BUTTONS IF YOU ARE OVERSEAS. EMAIL FIRST AS WE CANNOT SHIP DIRECTLY TO OVERSEAS DESTINATIONS. WE NEED TO USE A 3RD PARTY CARRIER.

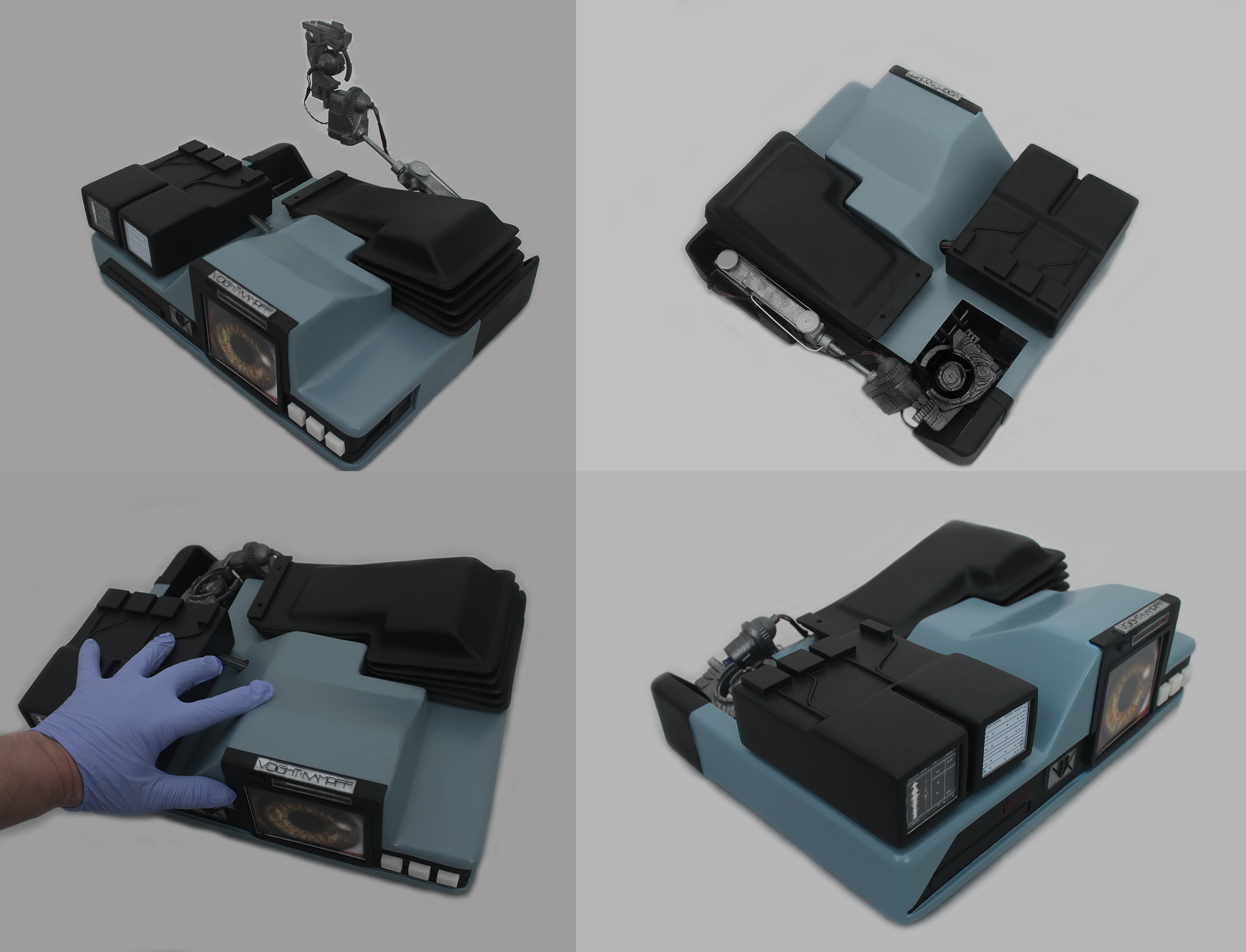

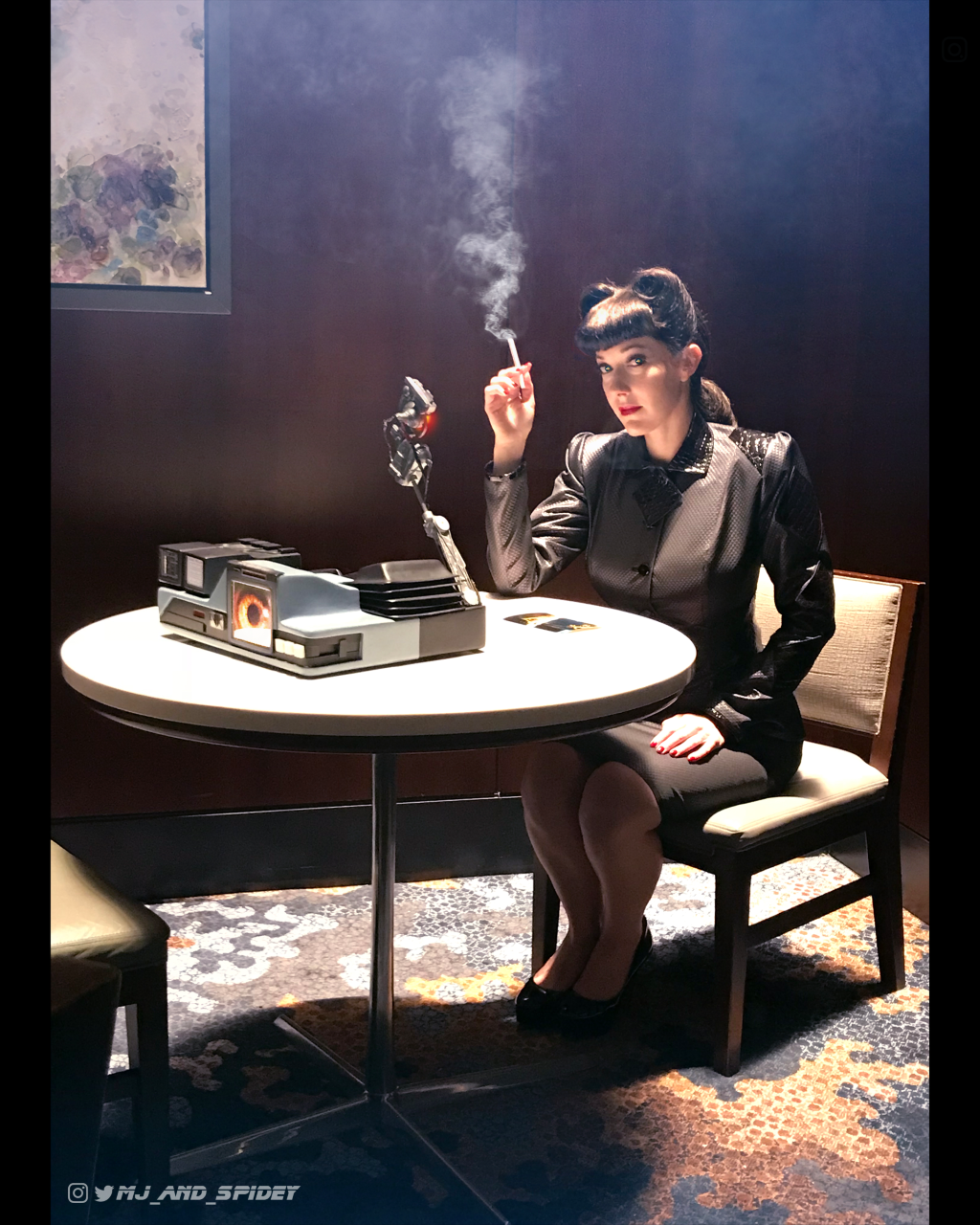

This is what can be done with this kit:

updated 2023

visit the Bladerunner 2049 Mini VK machine and BASELINE SCANNER

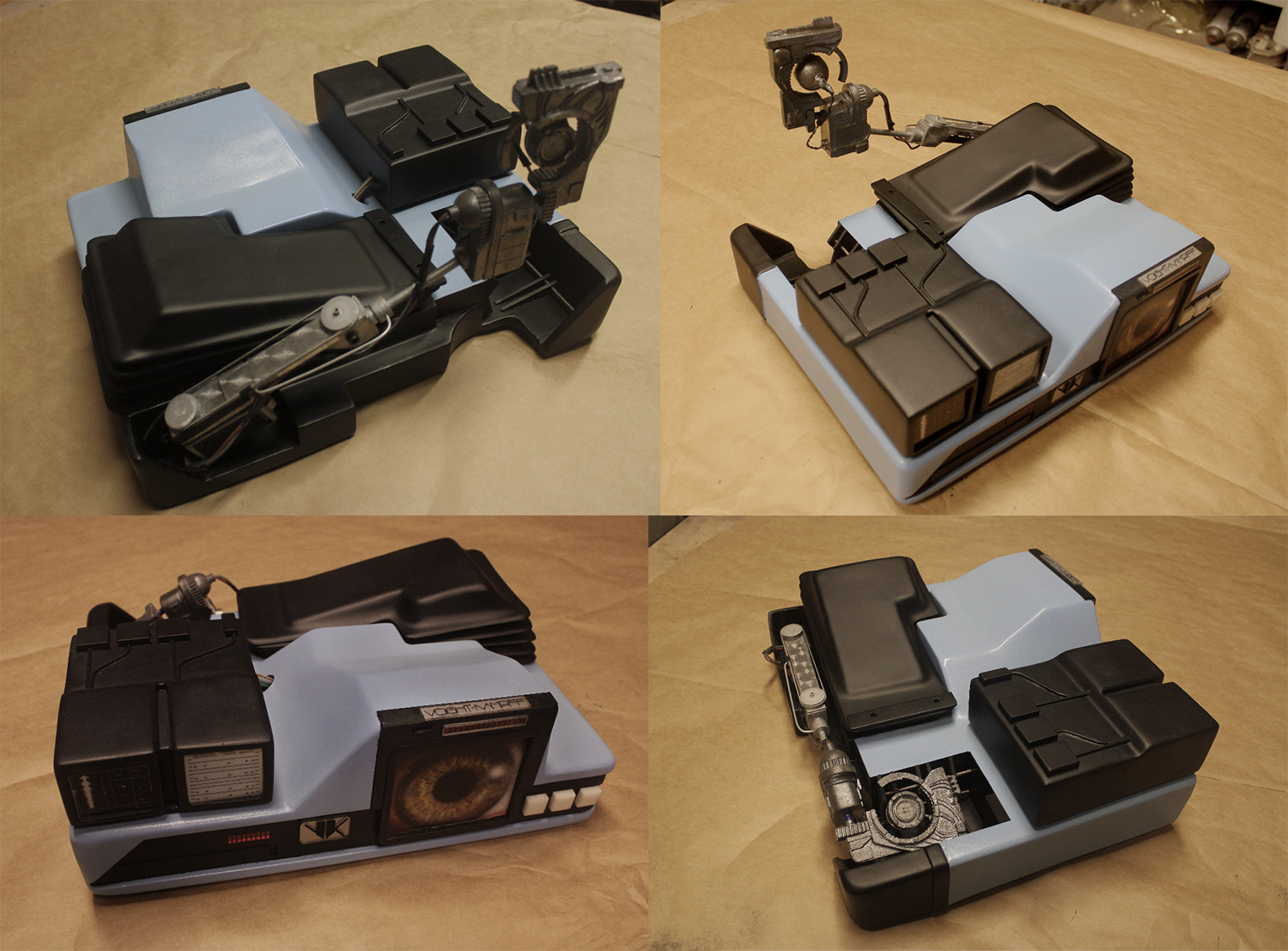

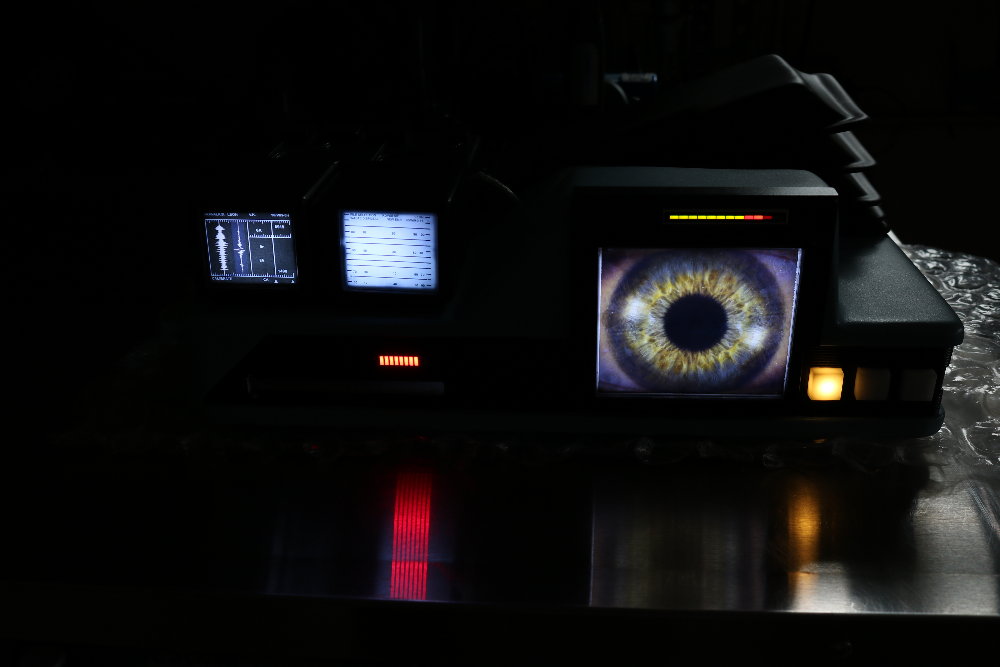

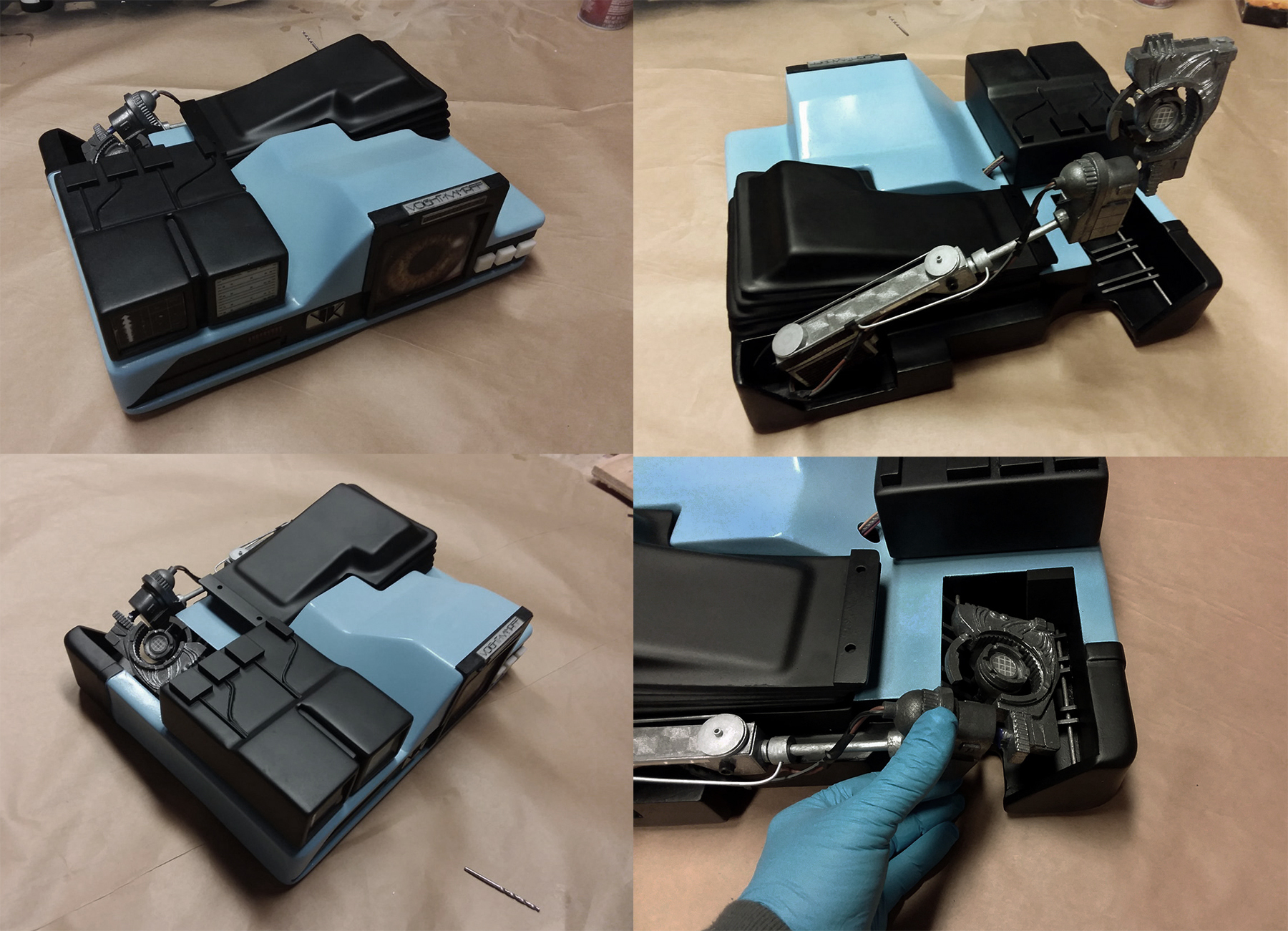

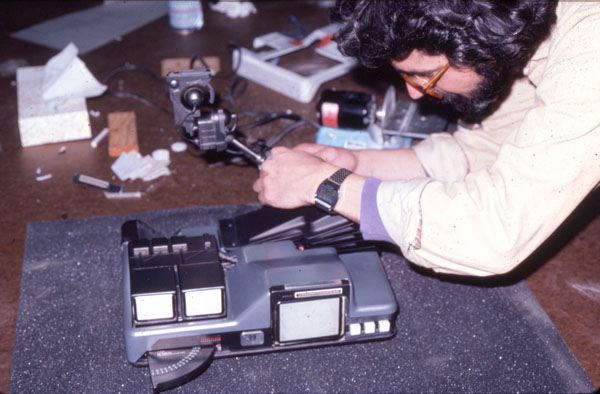

This is an example of expert modification on this kit using computer controlled servo animation. Build-up courtesy of Micke Askernas.

This is an example of expert modification on this kit using computer controlled servo animation. Build-up courtesy of Micke Askernas.

THE TUTORIAL IS HERE!

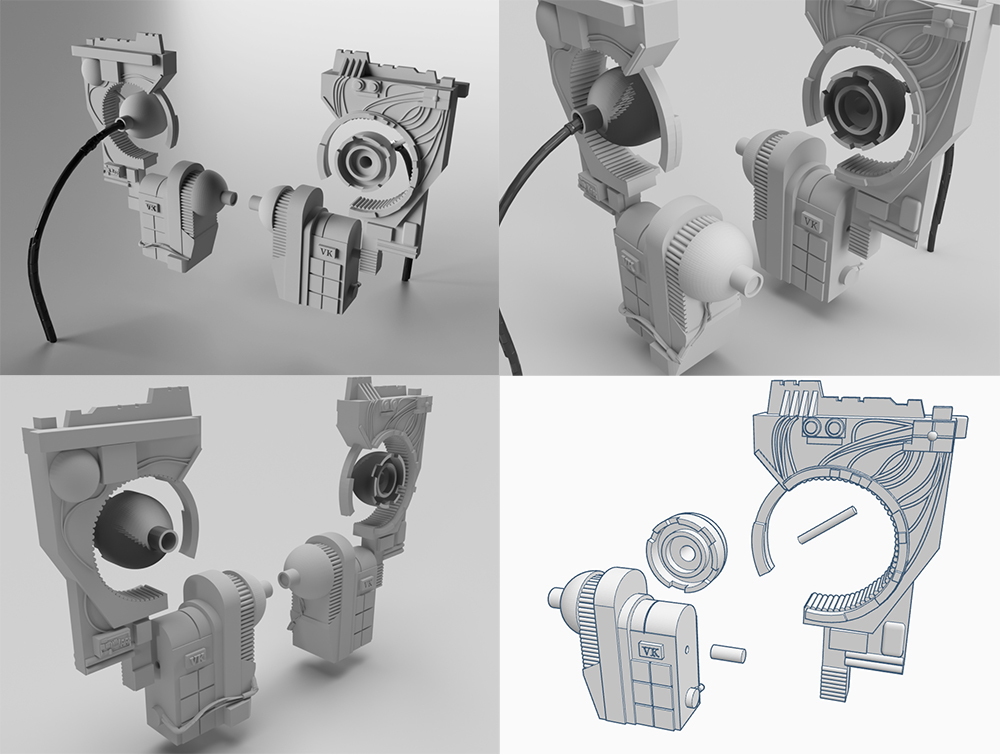

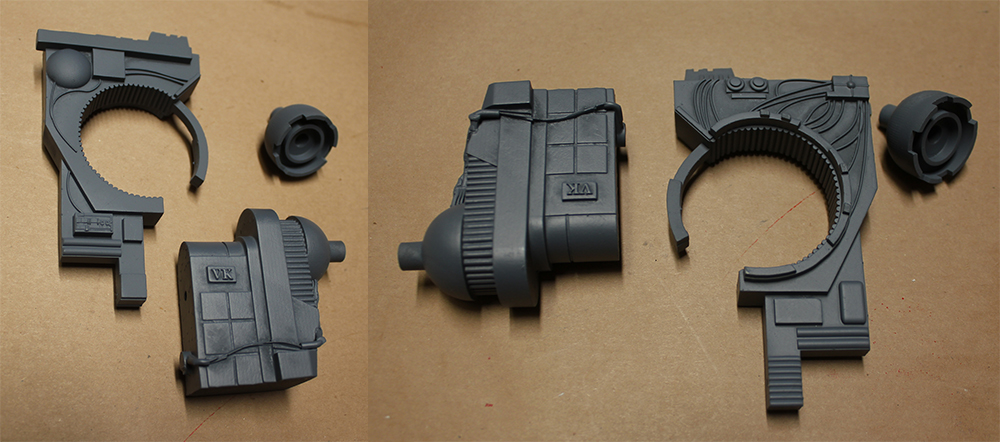

The kit shipping starting in 2023 now includes a retooled Eyepiece assembly (3 parts) expertly resin 3D printed.

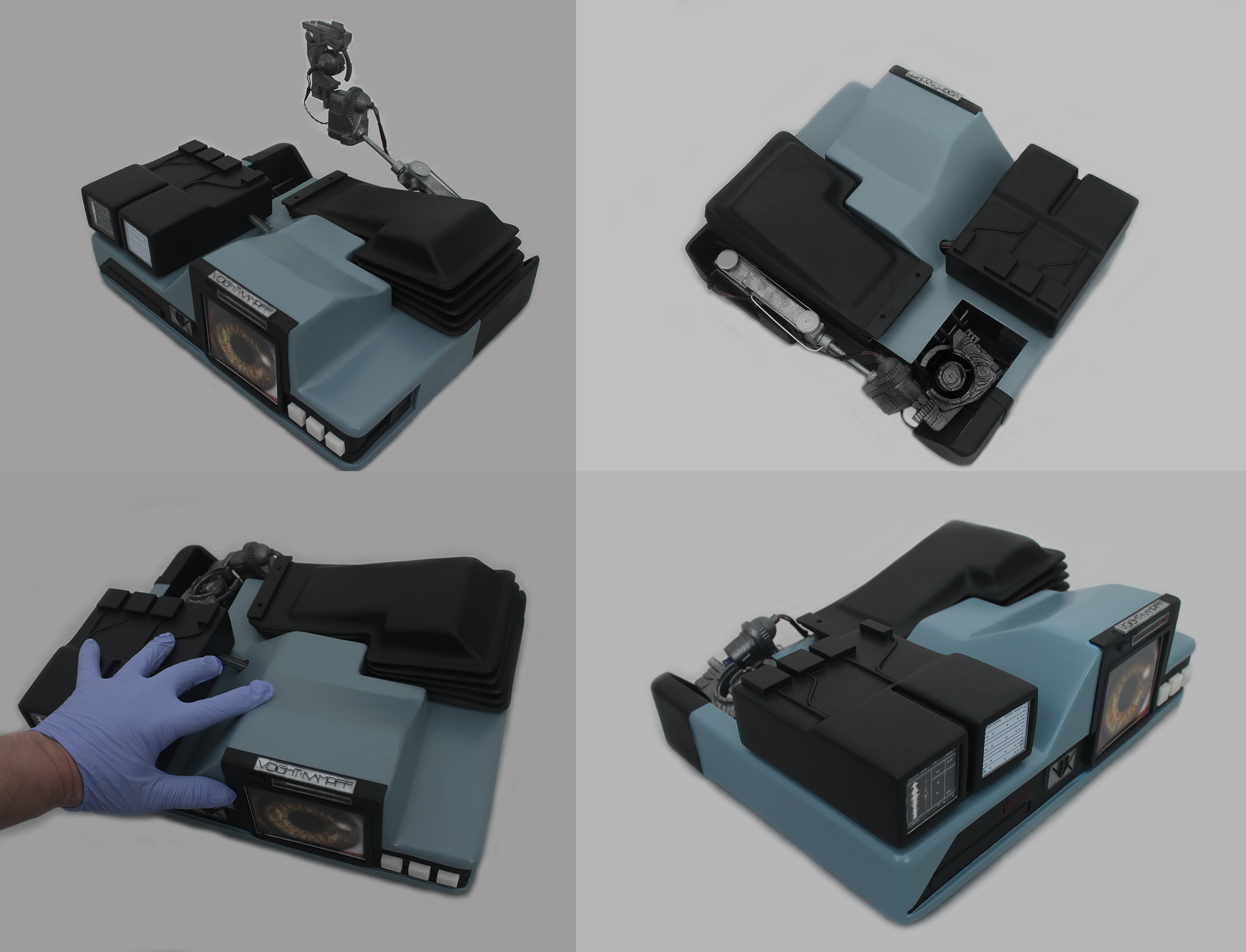

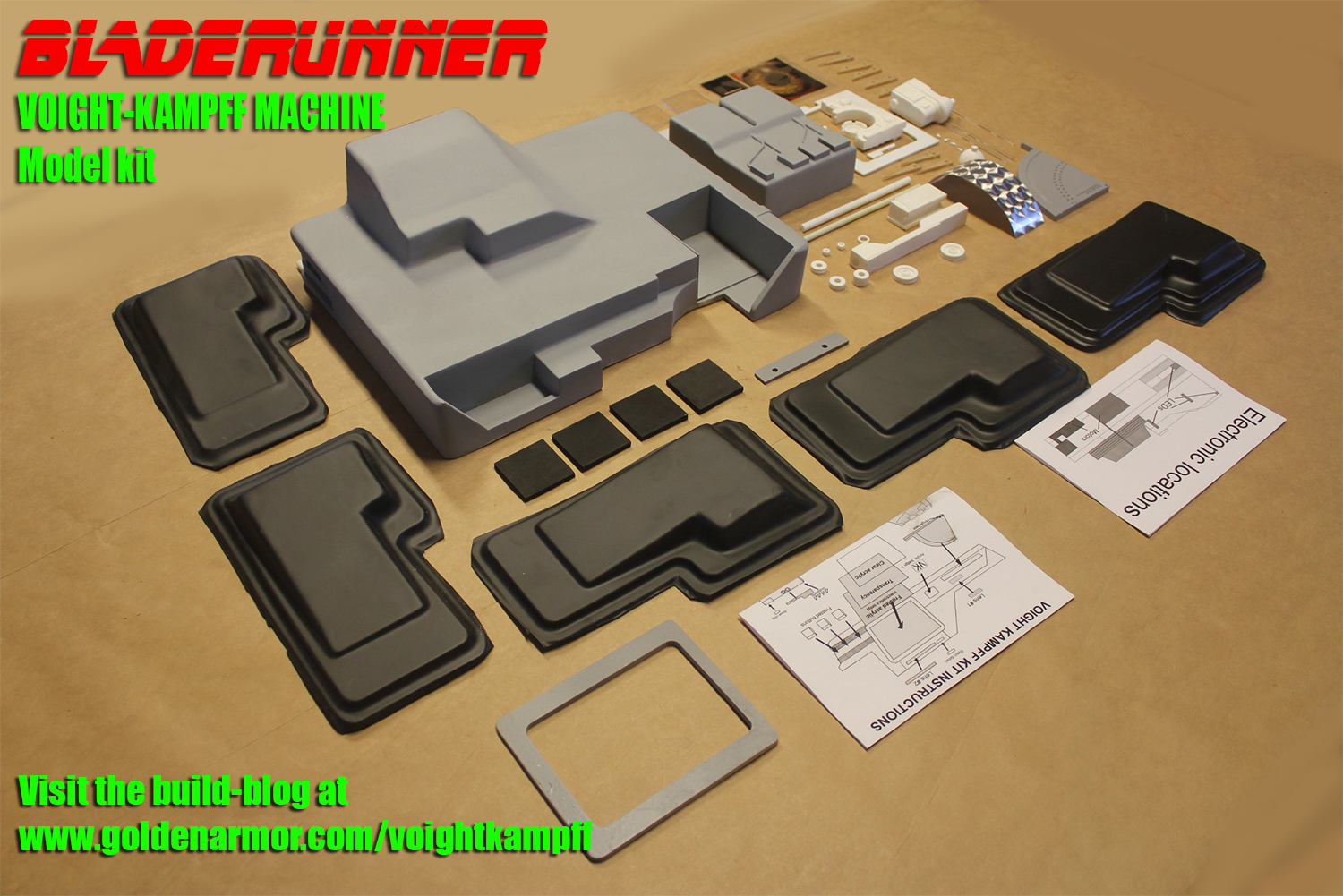

THE KIT:

**All kits are made to order and exchanges/refunds are not available.

MEASUREMENTS: The body is 15 1/2" wide, 12 1/4" deep. The height at the tallest point is 5 1/4" (from the base of the casting to the top of the large monitor. The lowest elevation is 2 1/2" tall.

The FULL VOIGHT KAMPFF DELUXE KIT includes:

1.) the VK body (rotocast resin cast as one piece) Trim a large square at the bottom to allow access to the interior to install electronics. This is a rotocat resin casting so it is strong, hollow and lightweight. The main screen will be easy to remove and replace (for an electronic screen replacement)

2.) 4 laser-cut foam pad feet

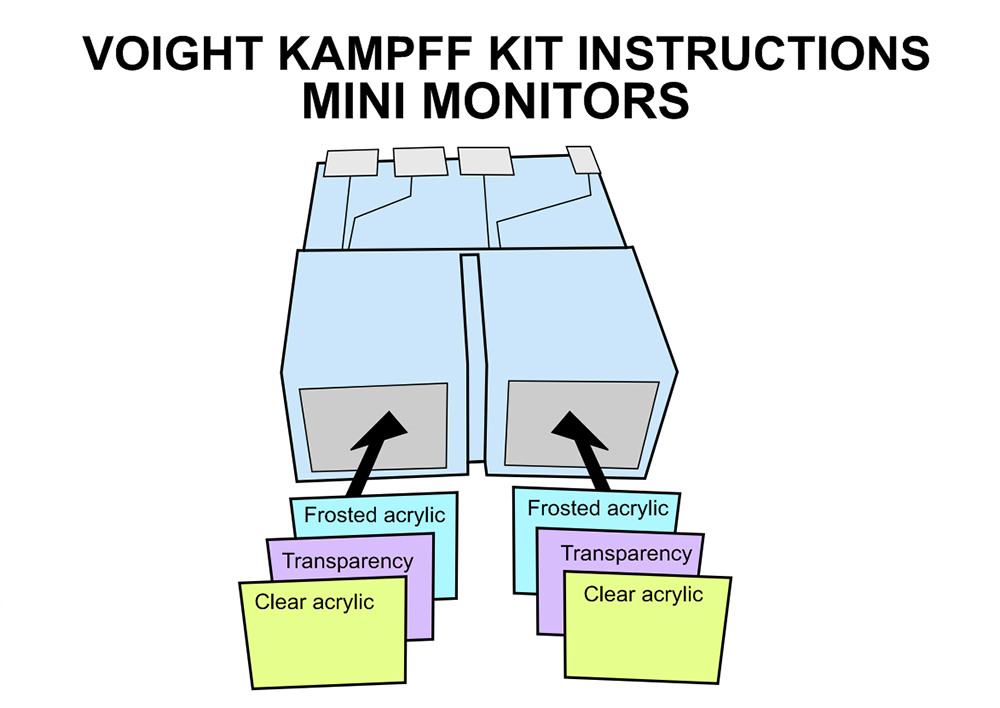

3.) mini monitors (one piece casting with an open bottom to allow interior access for electronics) Hollow-cast to allow for easy screens removal)

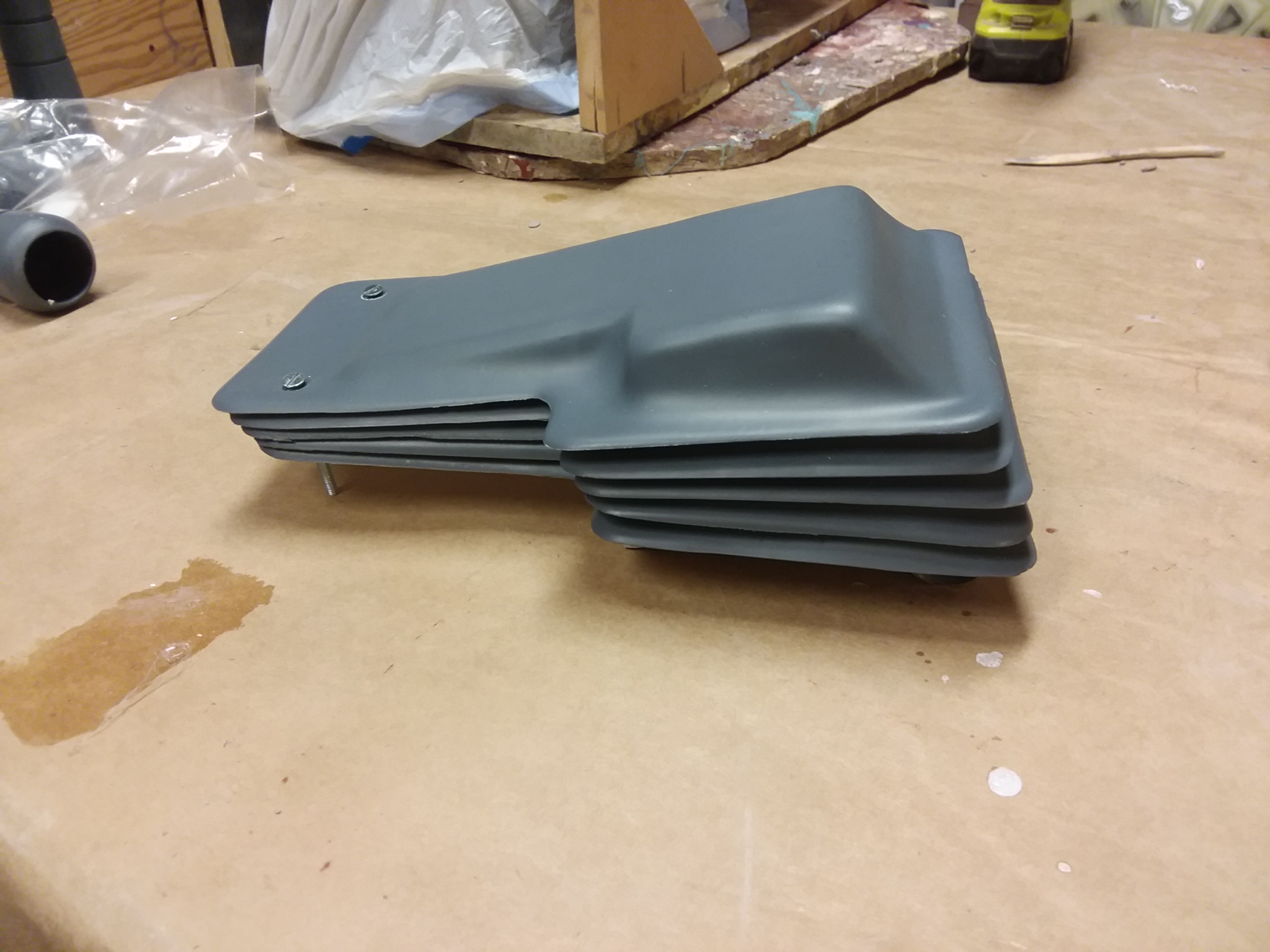

4.) set of 5 vacuformed bellows (untrimmed) These are thermal formed in .060 to keep them lightweight if you want to motorize the movements

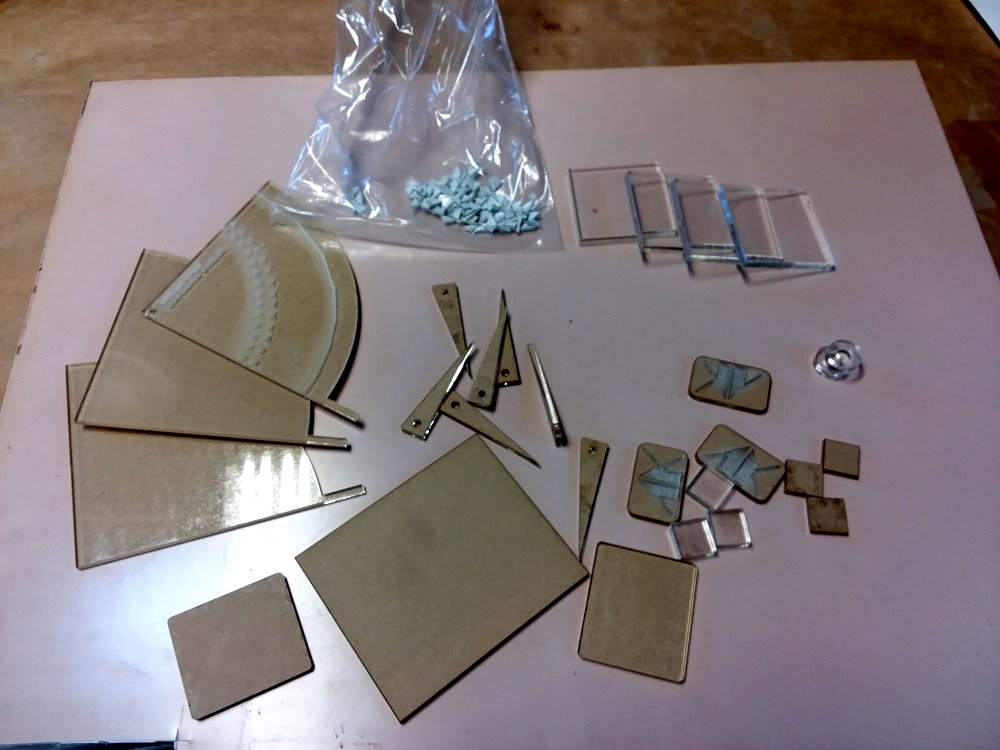

5.) 3 transluscent square buttons

6.) VK front plaque (laser etched acrylic)

7.) VK top plaque (laser etched acrylic)

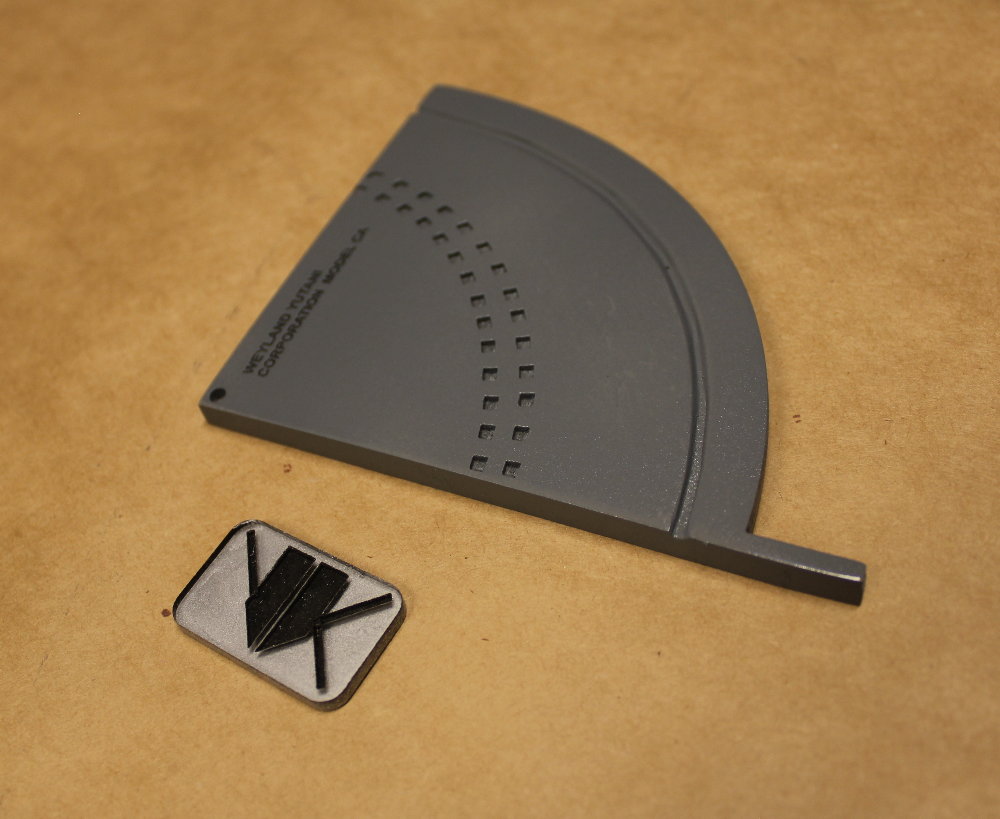

8.) swing-out tray

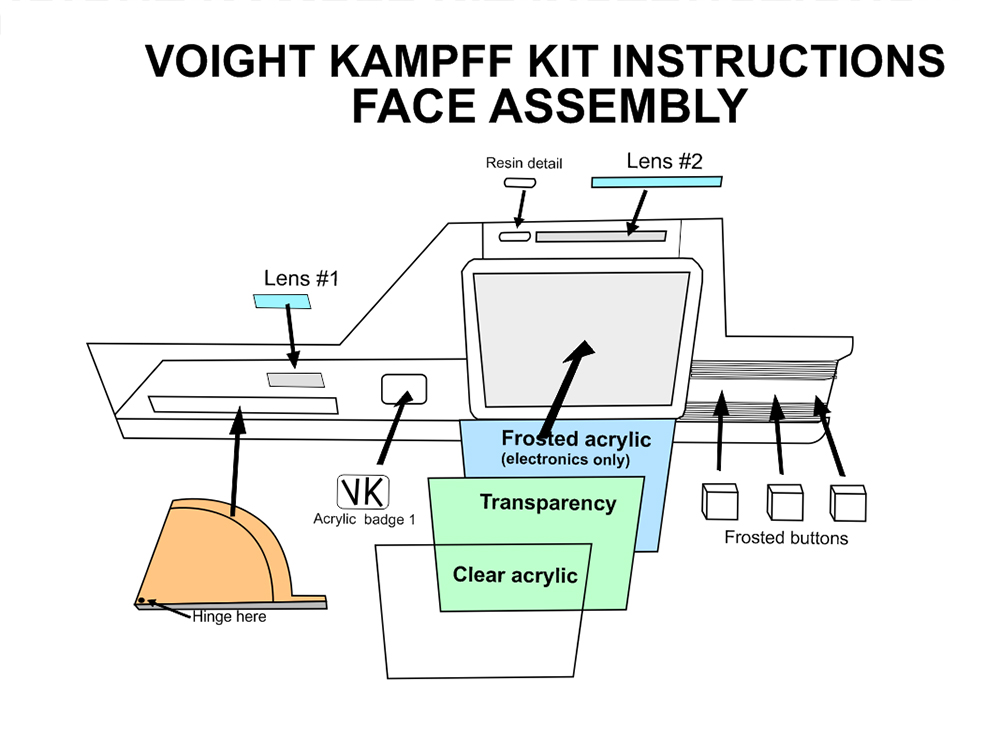

9.) set of 2 clear lenses (acrylic)

10.) mini monitor insert (laser cut styrene)

11.) mini monitor foundation

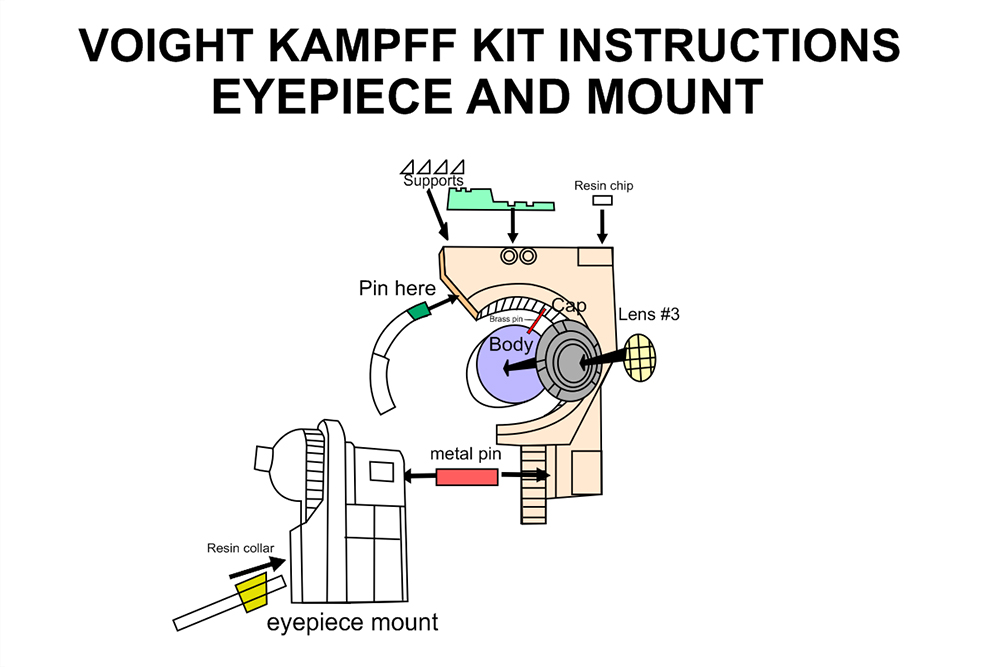

12.) eyepiece body

13.) eyepiece lens (laser etched)

14.) eyepiece fin

15.) eyepiece fin mounts (X4 ,laser cut styrene chips)

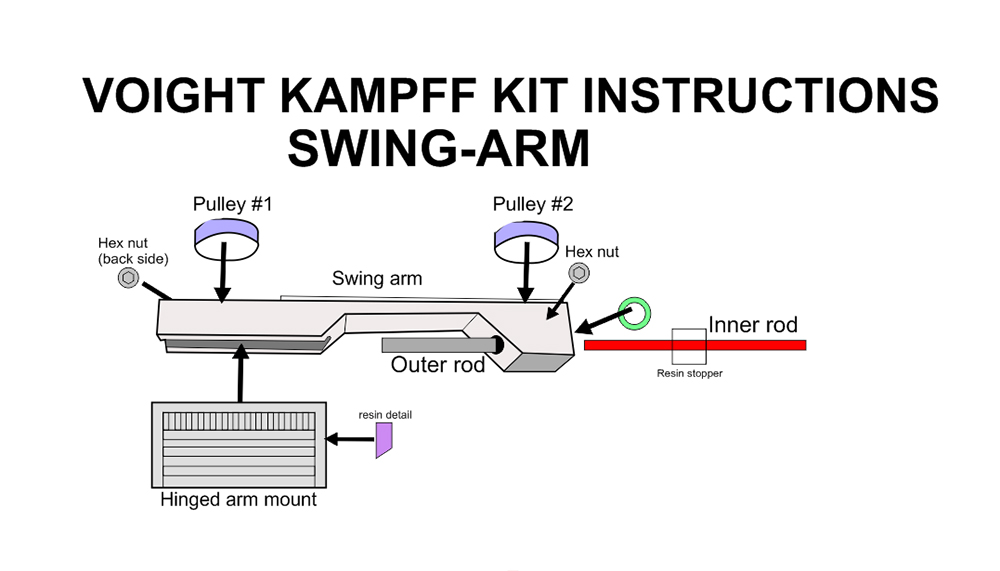

16.) swing arm

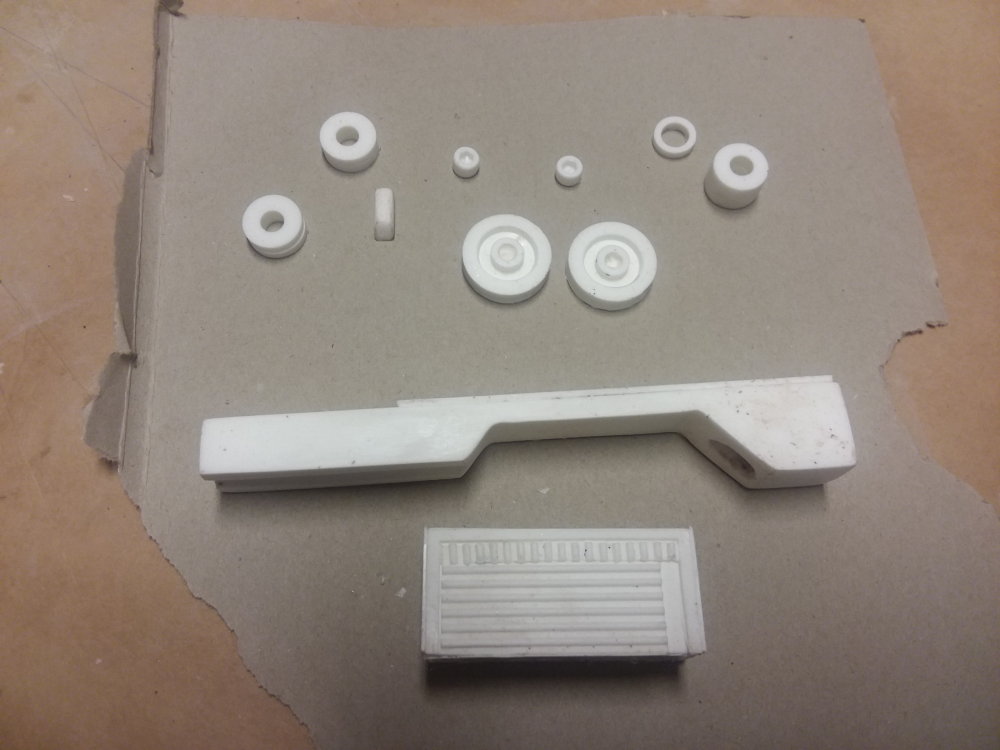

17.) swing arm motor (resin casting)

18.) swing arm hex nuts (X2)

19.) swing arm motor detail chip.

20.) monitor chip (resin casting)

21.) swingarm piston rings (X3)

22.) swing arm outer rod (plastic)

23.) swing arm inner rod (fiberglass)

24.) your choice of opaque screens or transpareny screens (X3)

25.) 3 screen windows (1/16" laser cut acrylic)

26.) **3 opaque laser cut acrylic screen windows (**only needed if you plan on lighting the 3 monitors)

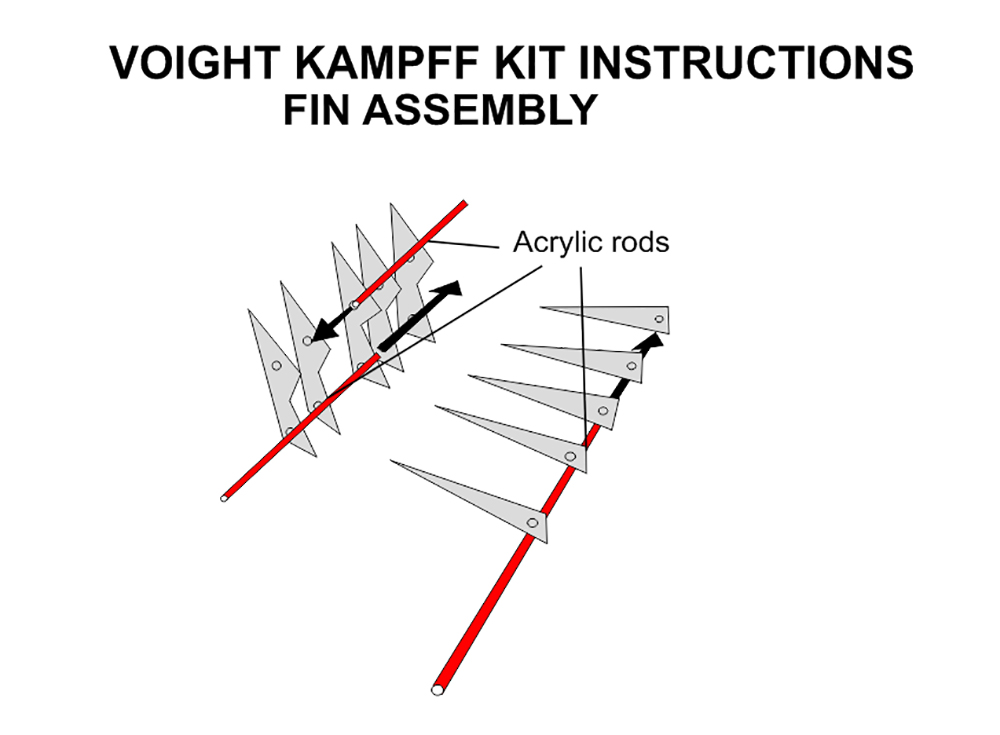

27.) 3 lenghts of acrylic fin rods

28.) set of 5 tall fins (laser cut acrylic)

29.) set of 5 short fins (laser cut acrylic)

30.) eyesensor ball

31.) eye sensor faceplate

32.) brass rod for the eye sensor

33.) holographic tape (for the swing arm)

34.) conversion kit (2 laser cut panels) for the US version prop

35.) Trench brick detail

36.) baggie of wiring/cable

37.) laser cut swing arm mount plate

**the BASIC KIT is at a reduced cost and does not include parts you can buy at craft stores and make at home. The basic kit does NOT INCLUDE any of the plastic, metal, acrylic or fiberglass rods, does not include any of the laser cut opaque or clear screens, does not include any wires or holographic tape.

The main body and mini monitor assembly are rotocast to allow a hollow interior for installing electronics. Just cut out a 7X7 square at the bottom of the main body to access the interior for lighting purposes. There is room enough to install LCD screens and an actuator to articulate the baffle and swing arm. (for advanced builders).

**the electronics package is in development by voodoofx.com. Contact my associate Randy at fxshop@yahoo.com for more information on the various levels of electronics for the VK machine. We are developing a basic lighting package (poor man's option), a more sophisticated animated lighting package that includes blinking and animated effects, a sound package to make your machine come alive, and we're even developing a servo operated mechical effect that will animate the bellows to 'breath'.

THE FOLLOWING TUTORIAL IS FOR THE ADVANCED BUILDER. It shows you how to mod the parts to to accept deluxe light packages and a DC motor to actuate the breathing bellows. Enjoy:

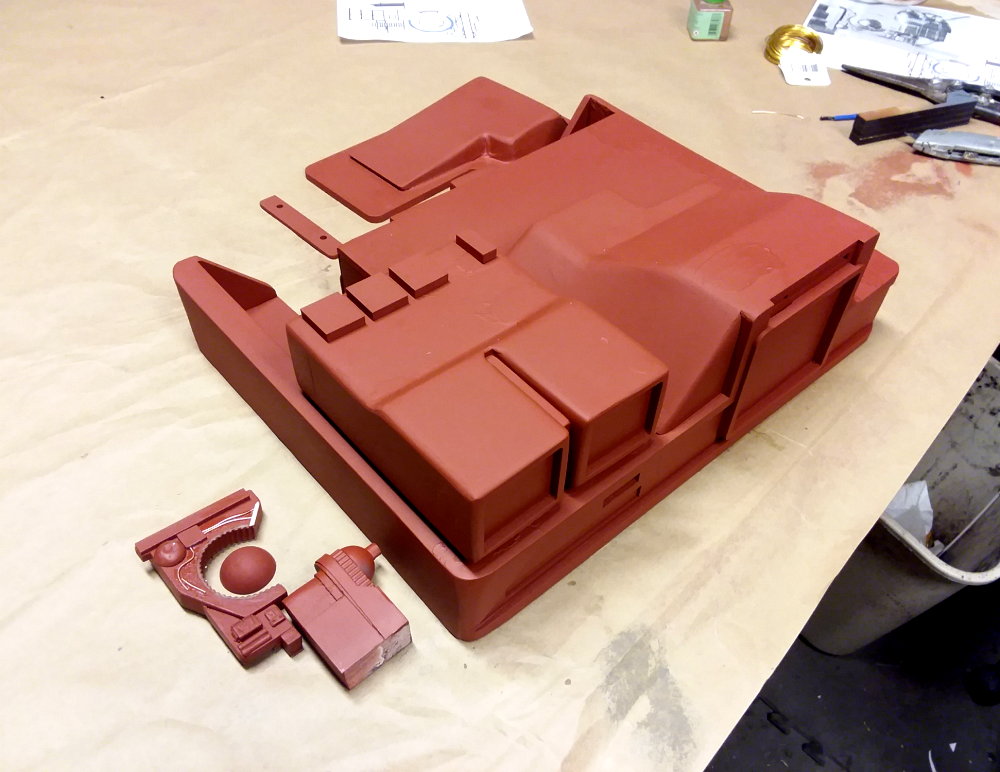

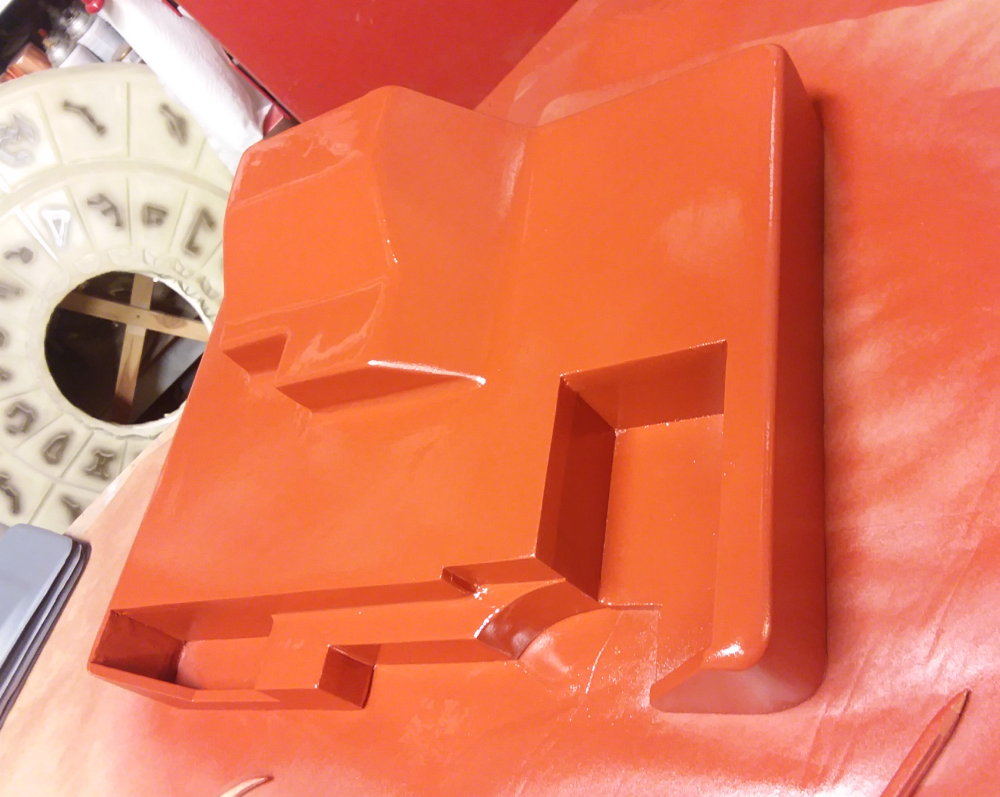

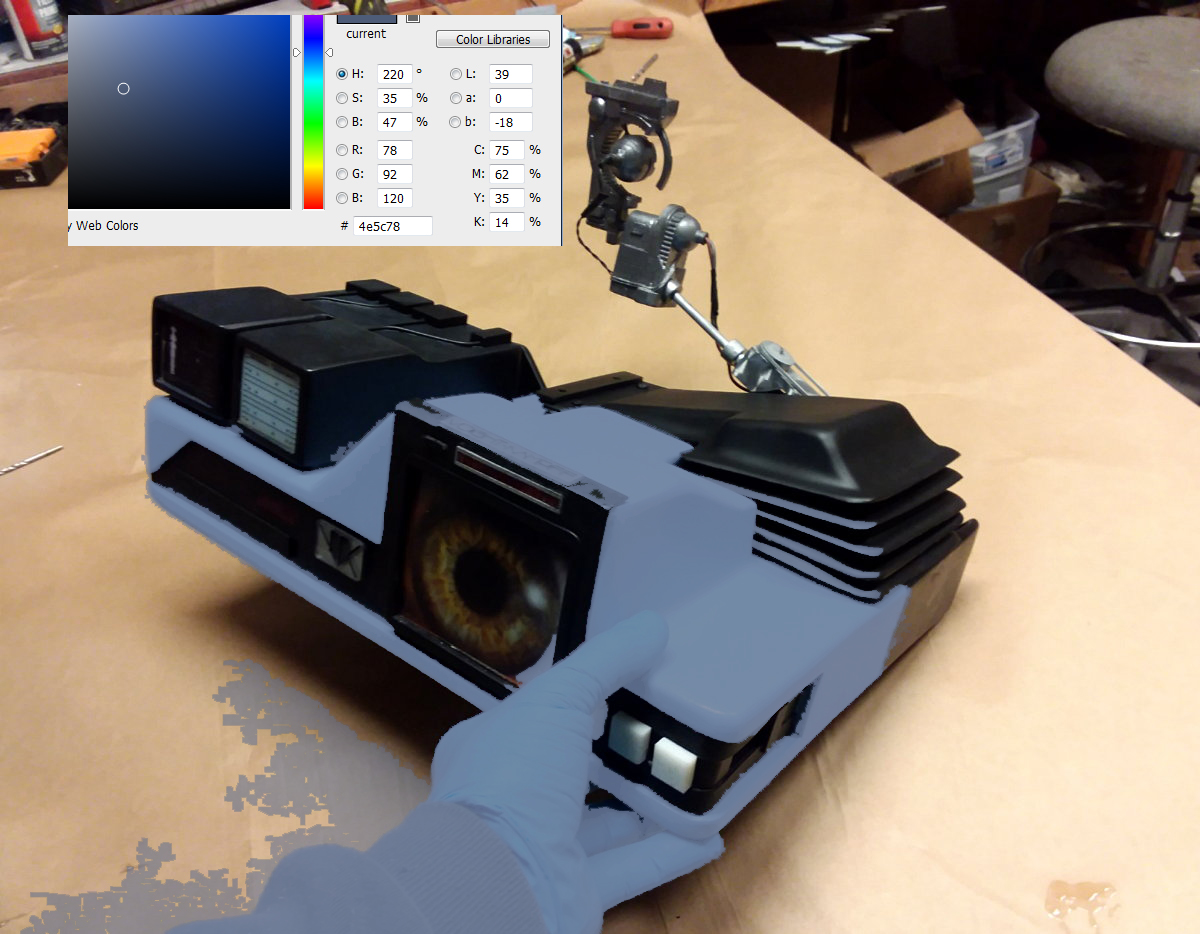

Here's a fast assembly testing color.

BUILDUP SAMPLE:

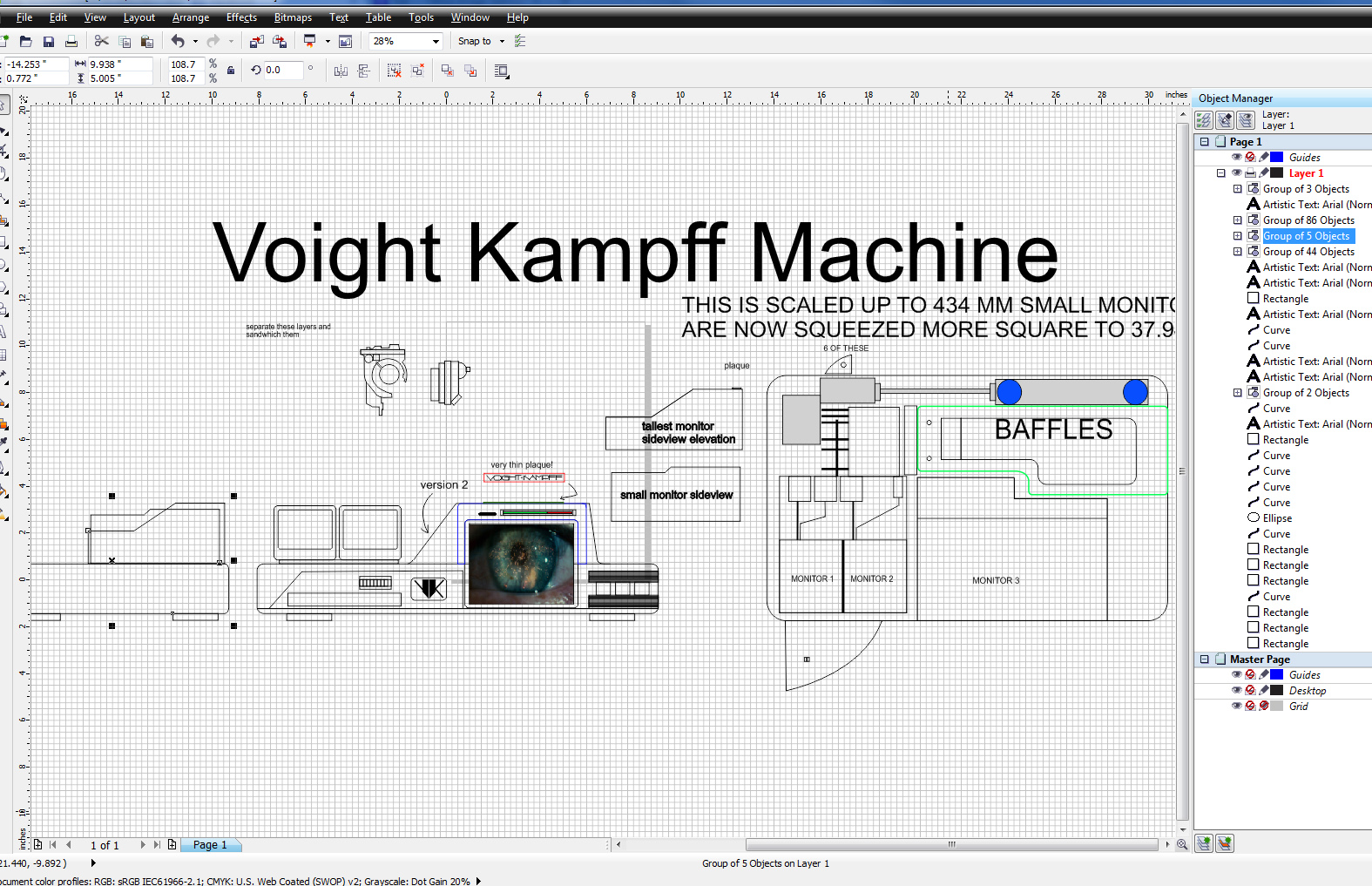

There were two VK machines made for BladeRunner. The UK version has a sunk-in face above the main monitor. For pickup shots in the U.S., a second machine was made that has a raised face above the main monitor. The casting, when left virgin, is the U.K. version. The kit includes the parts you need to make the U.S. version. Here's the difference:

email me if you'd like to be put on a wait list for a casting of this reproduction. impervium@hotmail.com

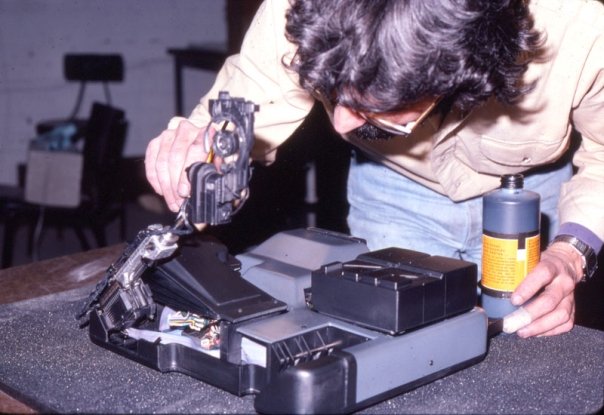

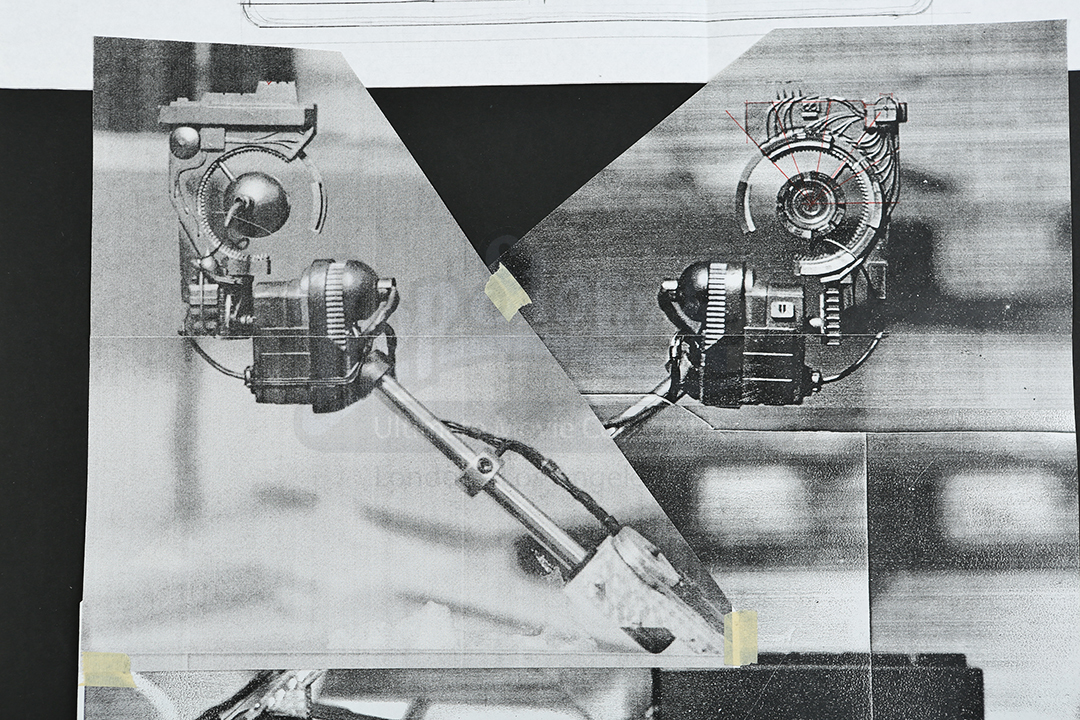

The Voight Kampff machine was needed to work on Monday, the first day of filming, so the prop makers brought it to Mr Scott, Mr Paull and the prop master on the Friday before to see it work. As it turned out, no one was happy. This team was dismissed and Mike Fink and his team was brought in to work through the weekend to create the VK you see in the movie. A new approach was tried and Mr Scott seemed to accept the new model. The bellows was made of a series of flatish vacuum formed vents that would rise and fall. This version was far more delicate and "intrusive" than the early one. The boom was finer than the one Syd had in his sketch.

On the front (the side Dekard sees) I put the VK logo plate. Just to the right of that is the TV screen, and sitting flat on top of that is the plate that says Voight Kampff (seen only if you are hovering right above the TV).

The script said the words Voight Kampff was finely etched so I found a modern German looking font (caps only) that was photo etched on a mag plate.

I offer all this to reward your efforts at trying to make this challenging prop. Not an easy thing to do. But have faith! It CAN be done!

HOW IT WAS MADE:

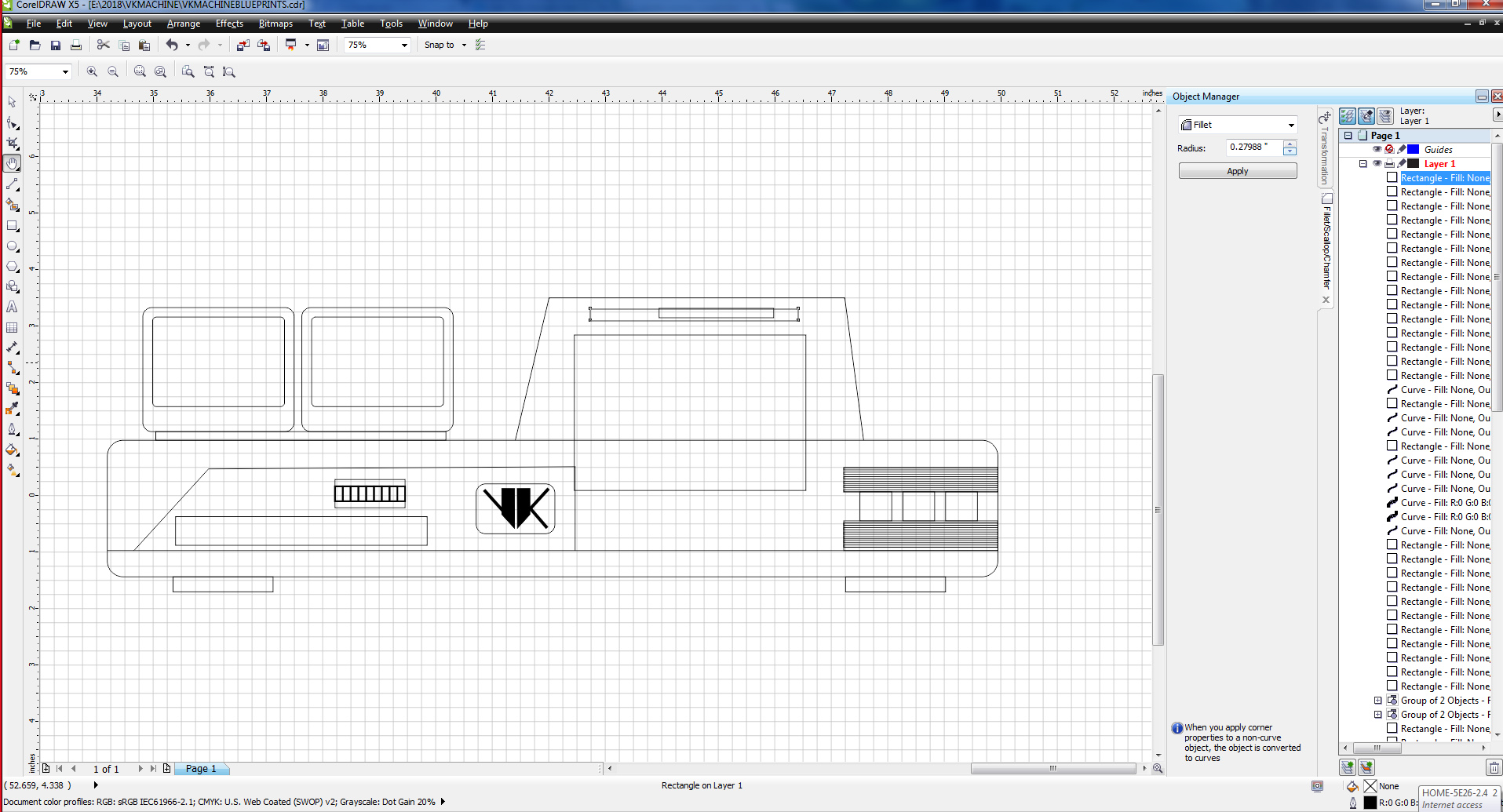

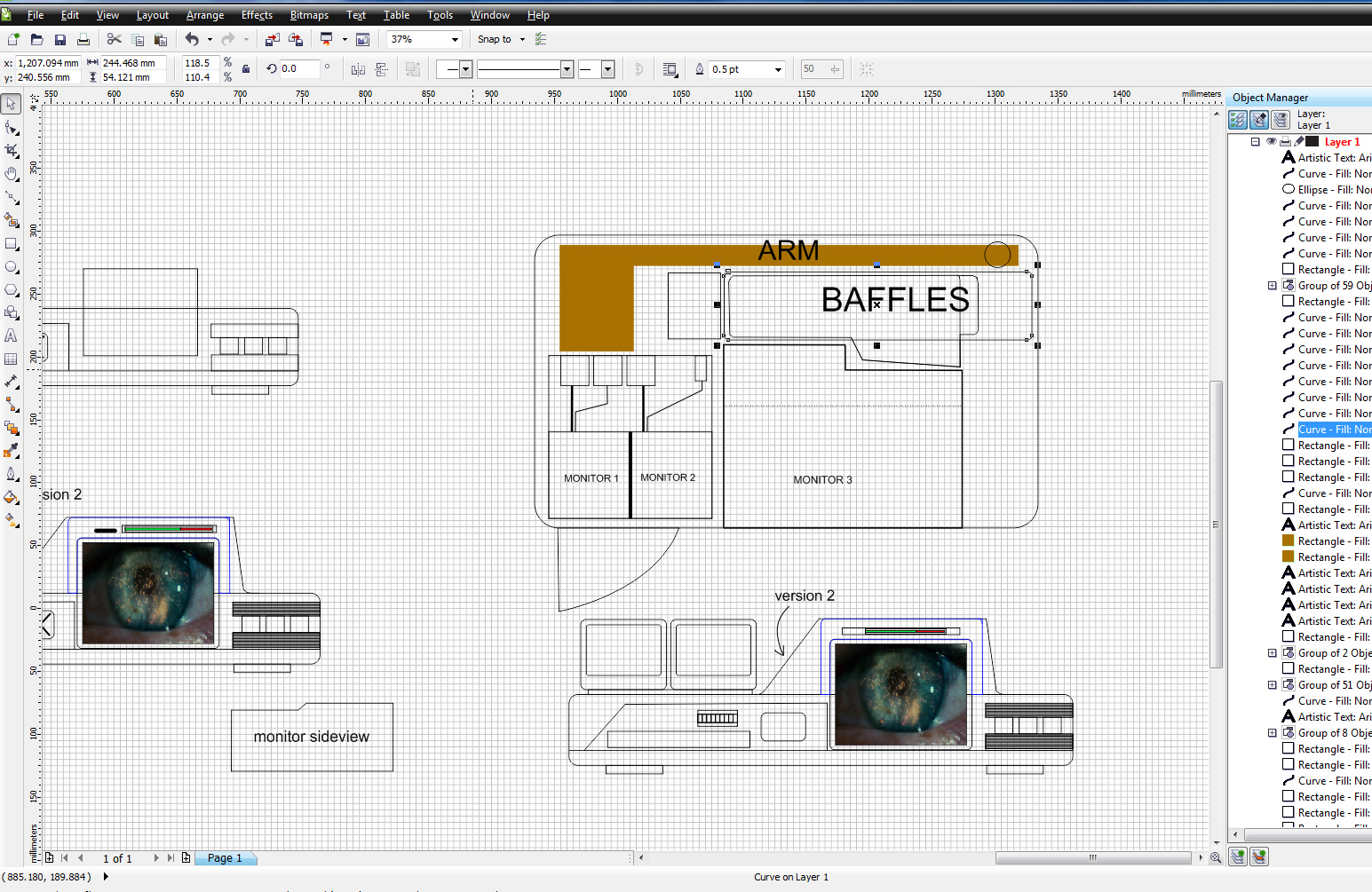

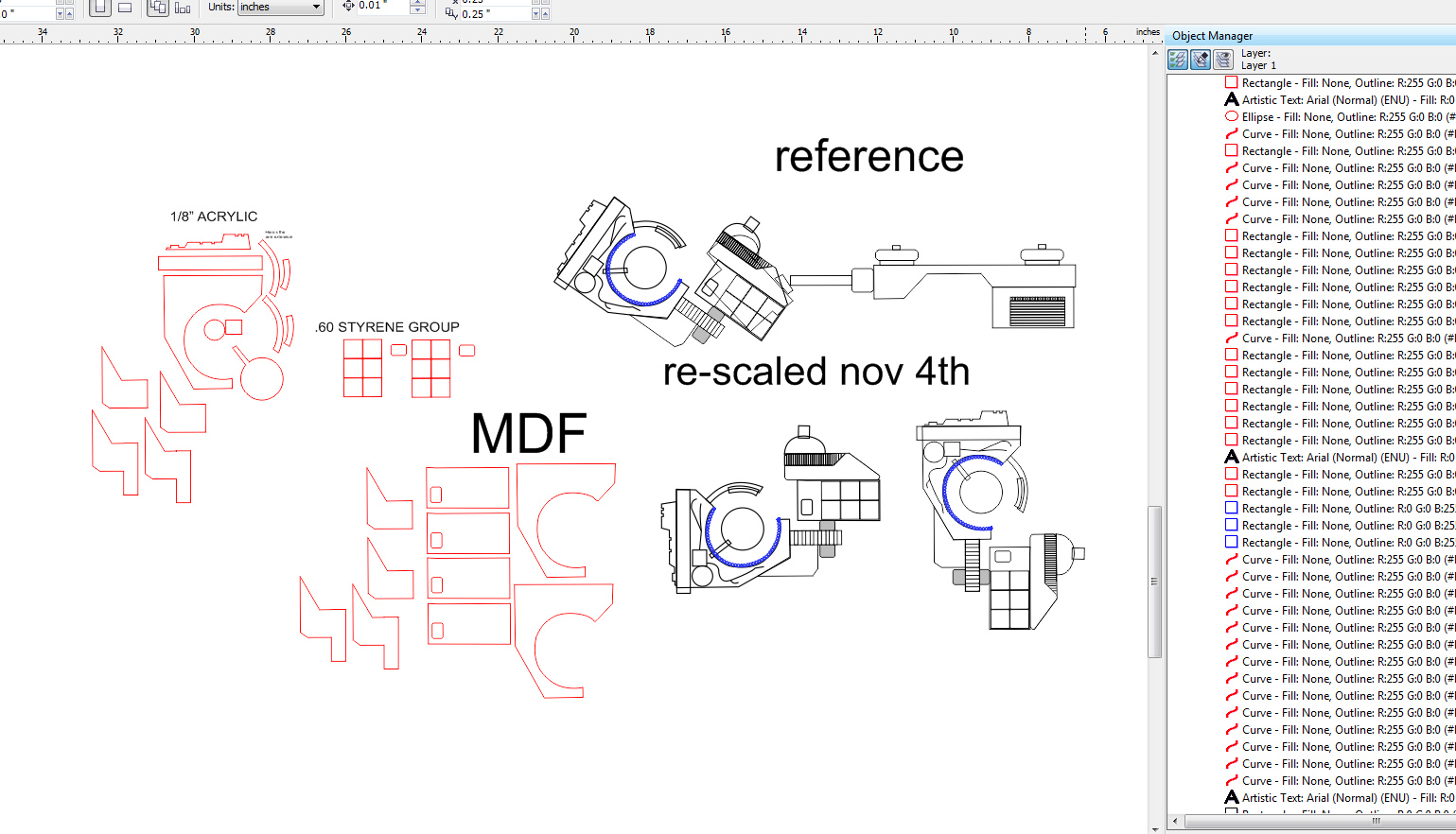

I started by studying all the reference photos of the original prop I could possibly find online. The online forum PROPSUMMIT was also extremely useful gathering information. From there, I started developing blueprints using CAD software. I designed and created the EAGLE 5 and YONDU FIN this same way.

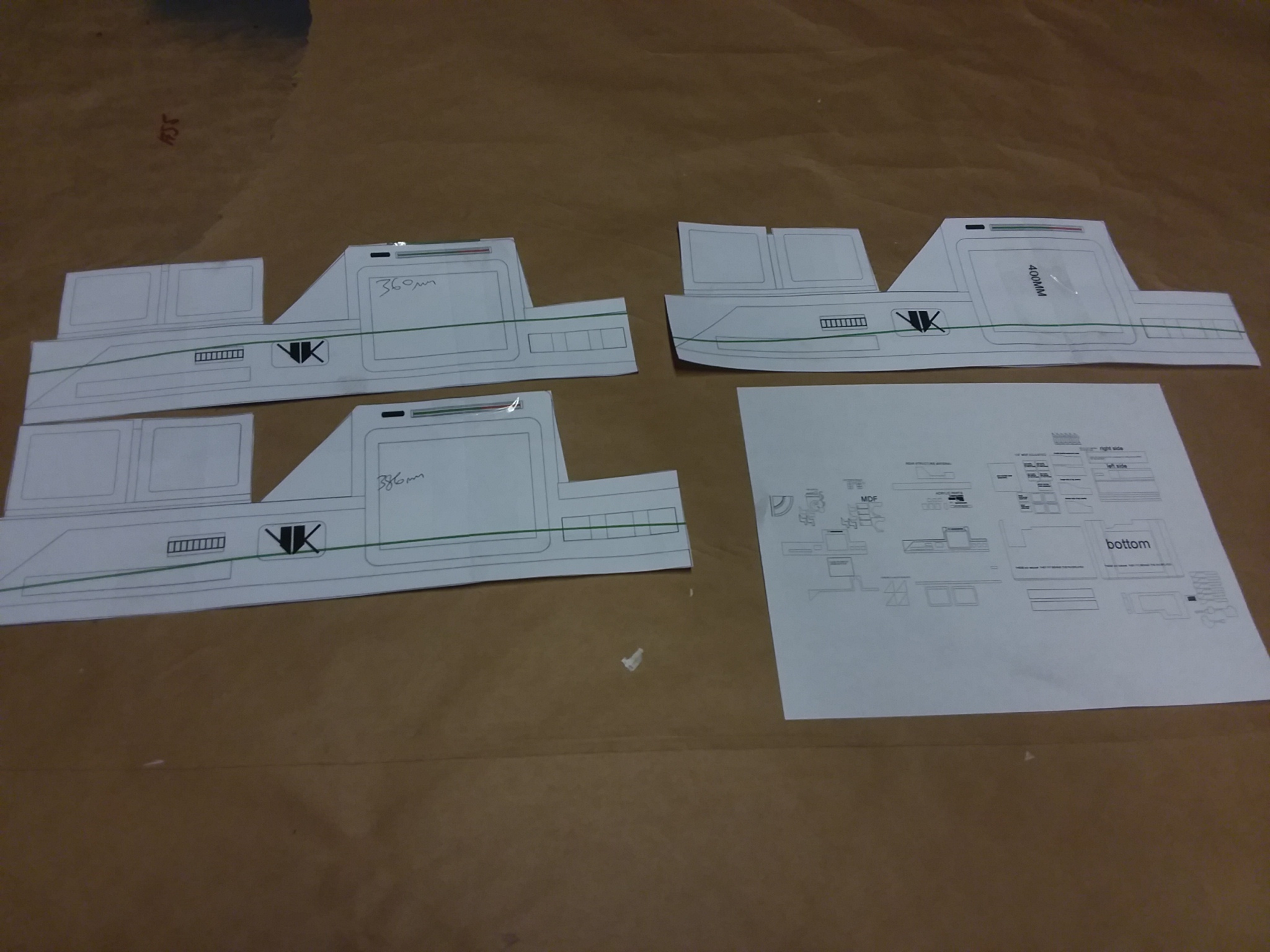

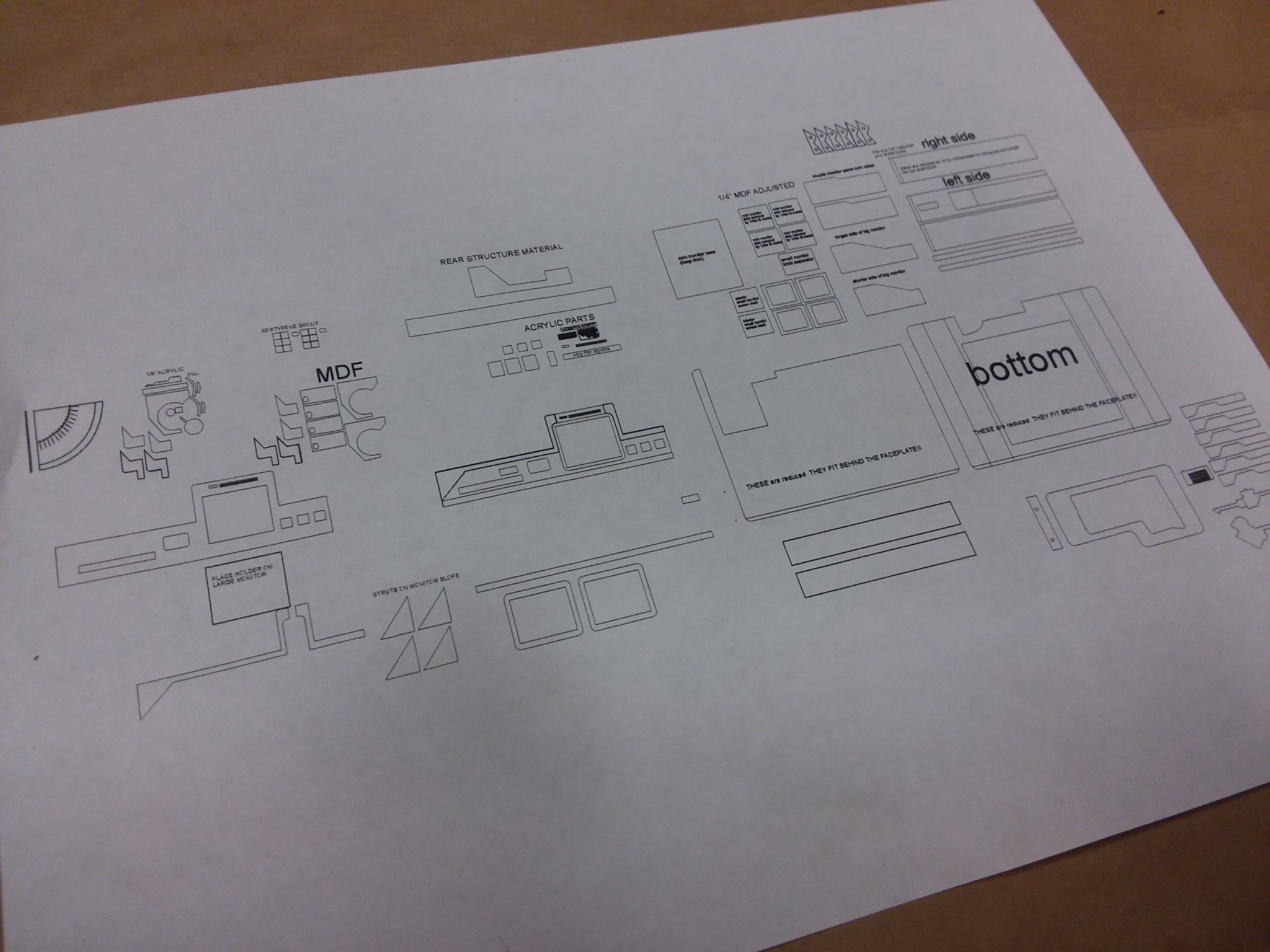

The vectors evolved until I had left and right profiles, top and bottom drafts, and vectors for individual components. I think of a 3D part and then imagine it flattened out into flat planes to be able to produce models using this technique.

A few days of development and I was ready for the next stage.

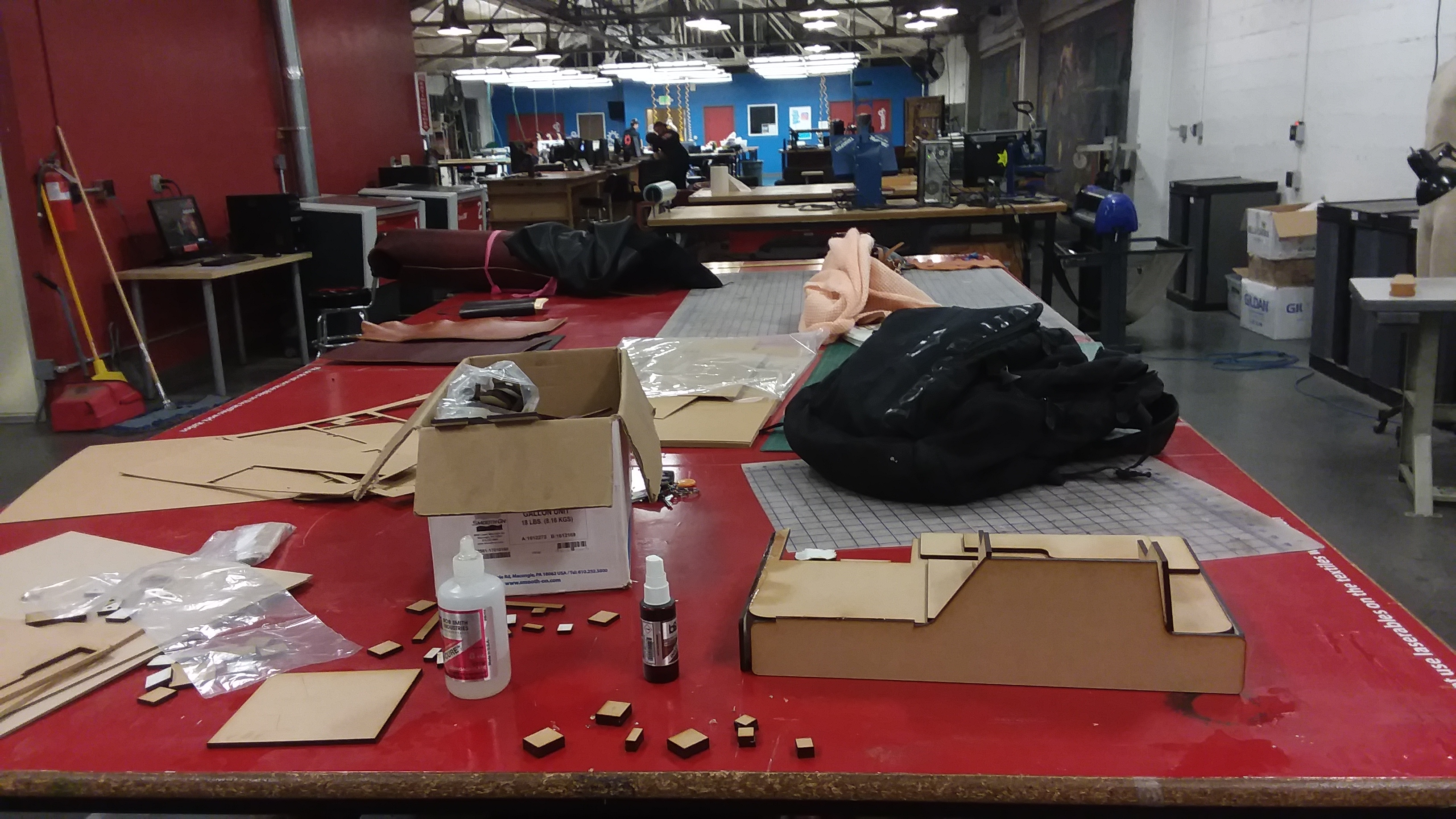

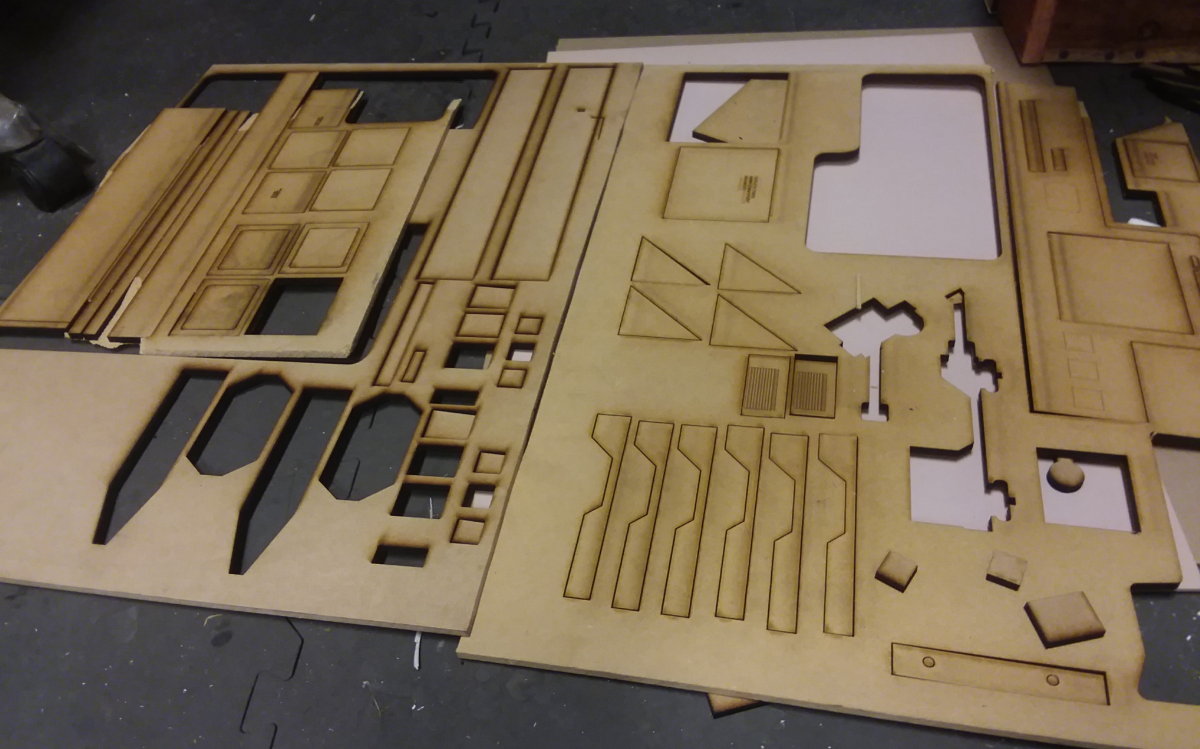

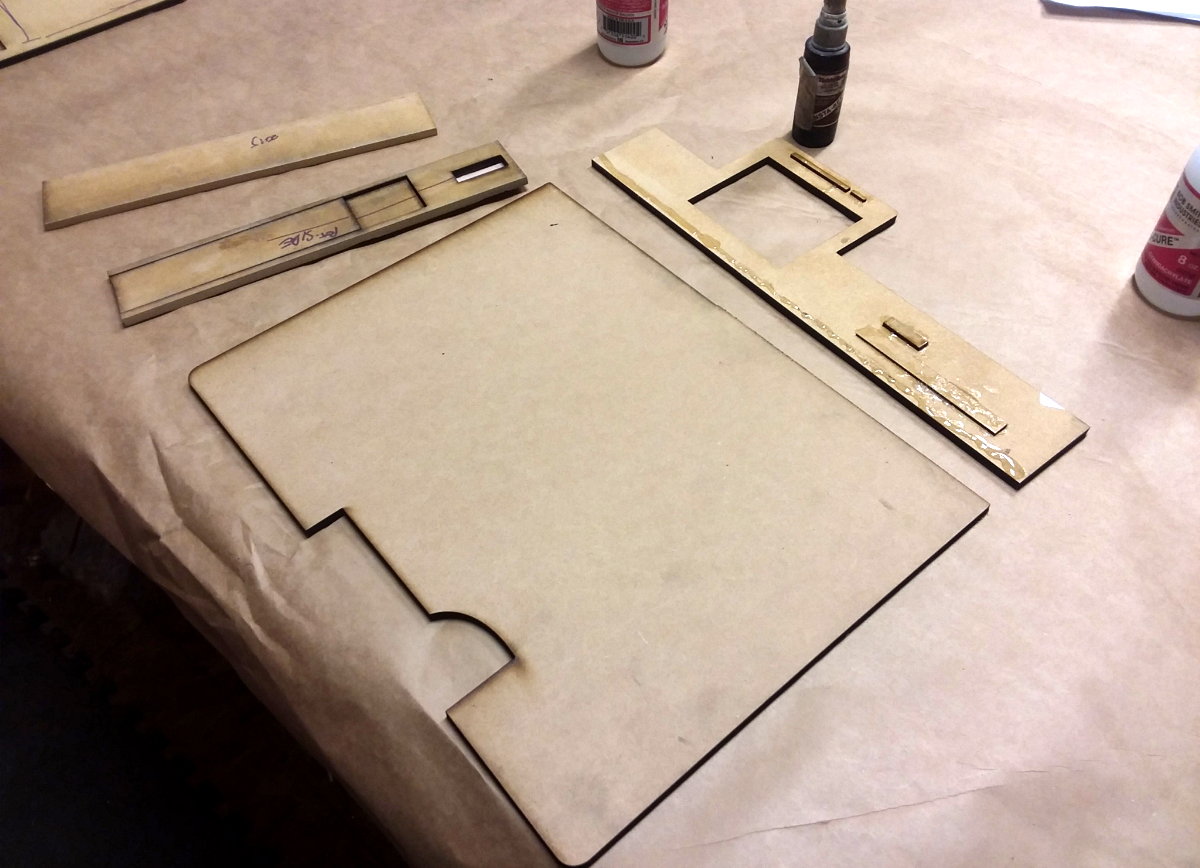

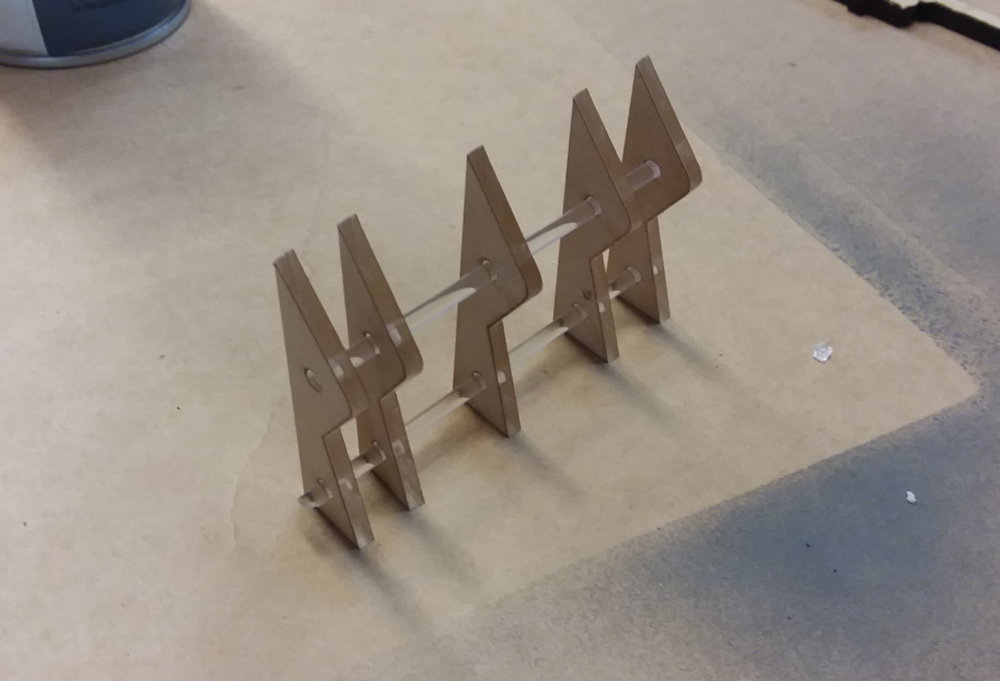

Time to start laser cutting cardboard and mdf! I do this at my local Maker Space.

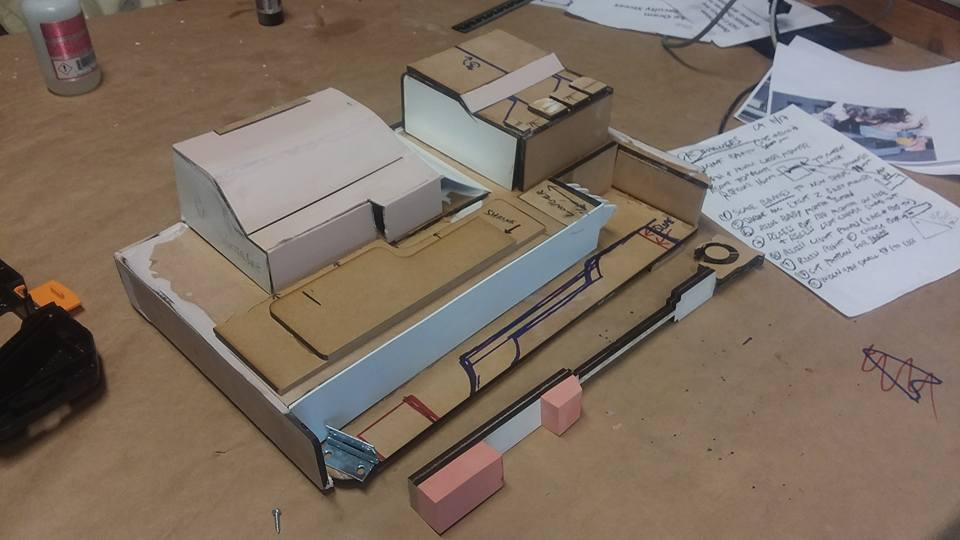

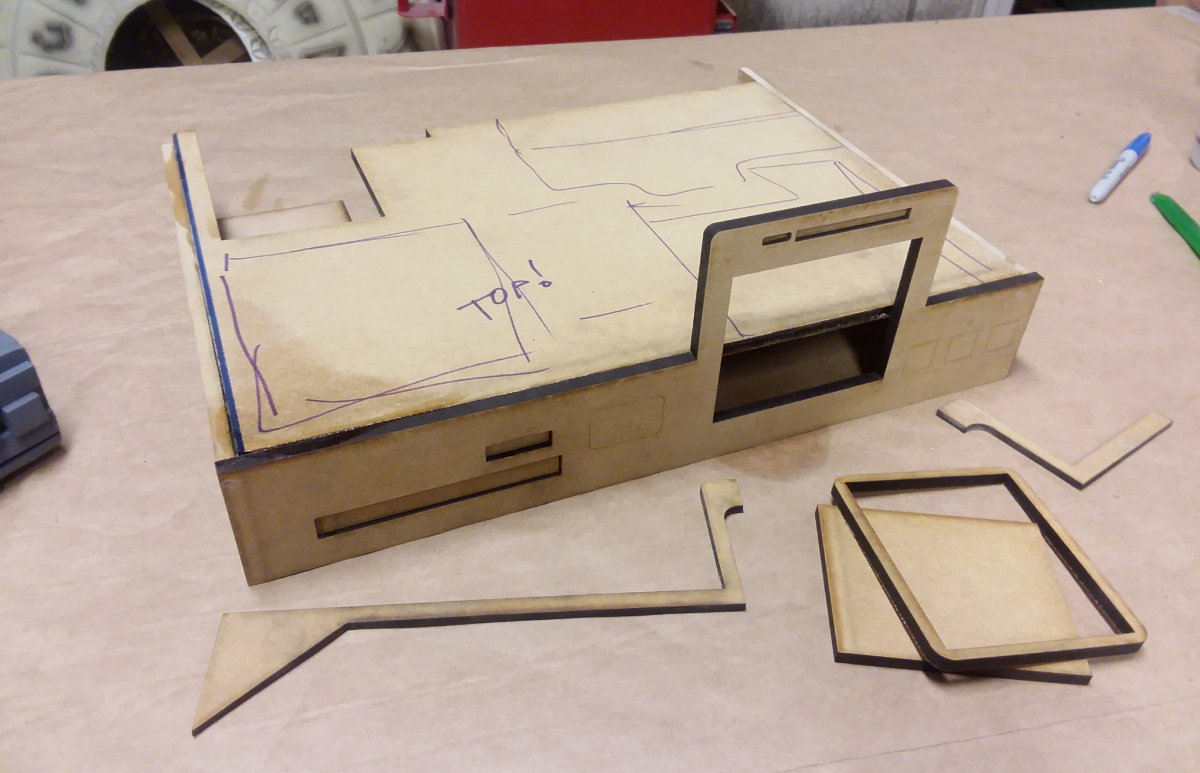

Rough assembly beginning to take form. I am not bothering butting edges up properly. I'm going for a quick and dirty build so I can start analyzing shapes.

This was the point at which I starting realizing the base of my VK machine needed to be less rectangular, by a good 2" at least (width-wise). I also needed to shrink it uniformly to about 380mm. This version was scaled at 430mm.

I used everything to build this rough study model from cardboard and clay to bondo and styrene. I took notes on changes I needed to make to my blueprints directly onto the model and took copious notes.

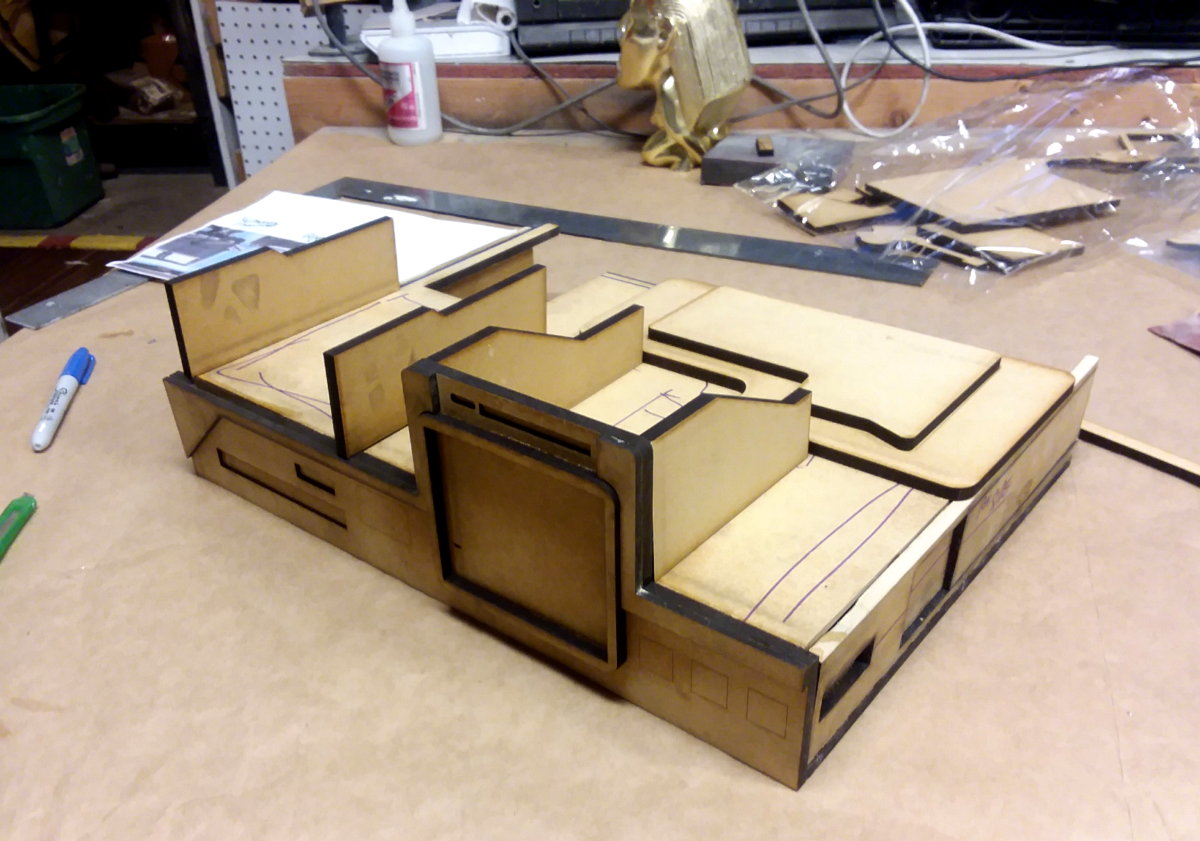

I took the study model as far as it needed to go. Not bad for two days of work. Now it's time to hit the computer for ROUND 2 of modifying my vectors with all the improvements that became obvious so far.

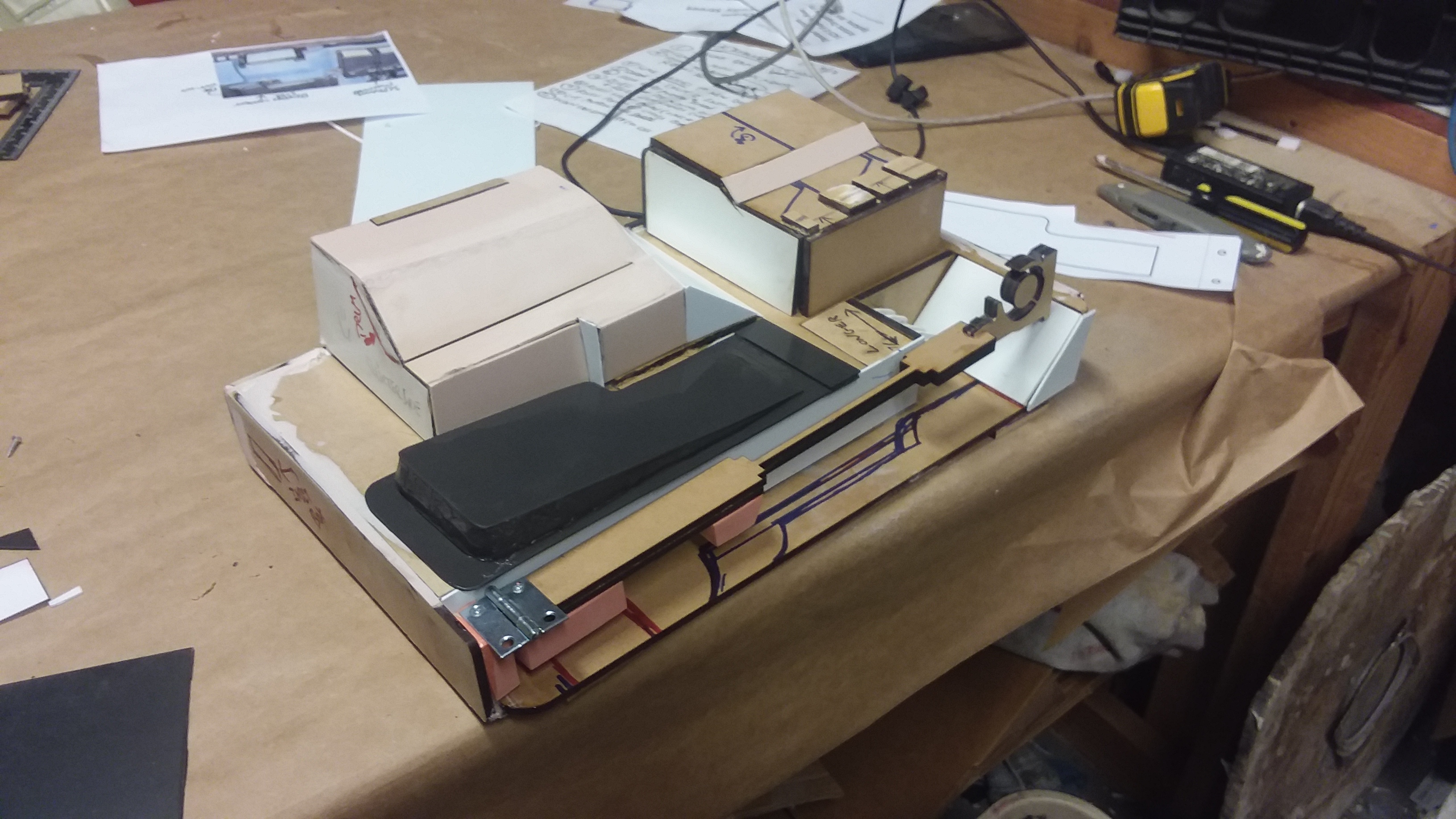

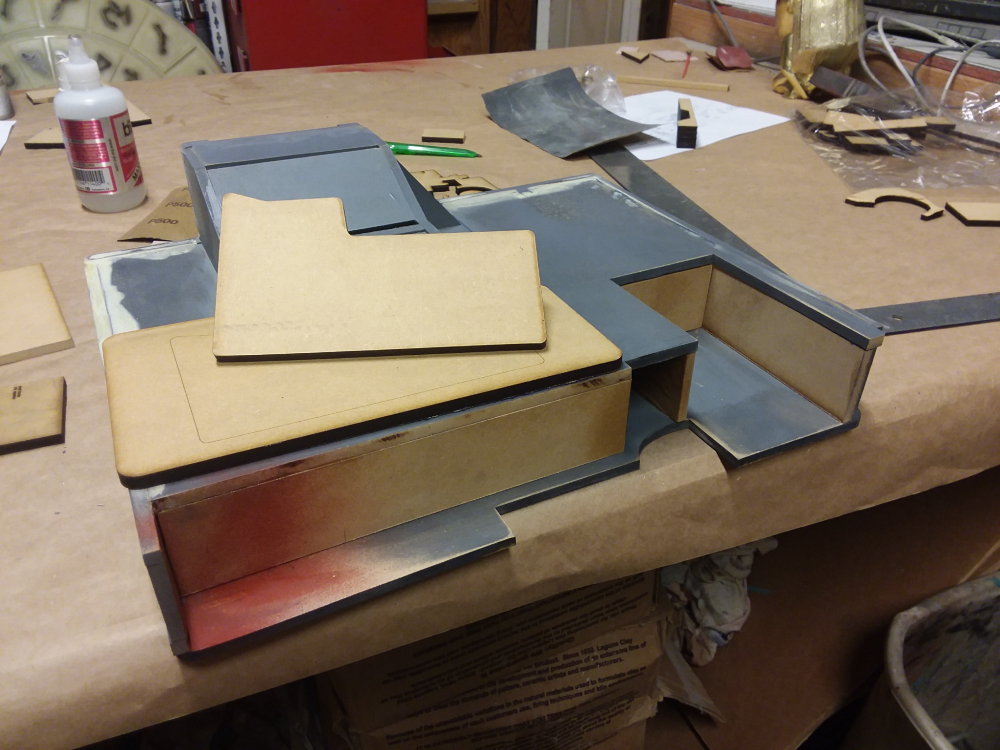

In addition to modifying my blueprints (I made several dozen improvements), I rescaled the depth of the machine and reduced the entire unit to 400mm wide after printing several versions on paper.

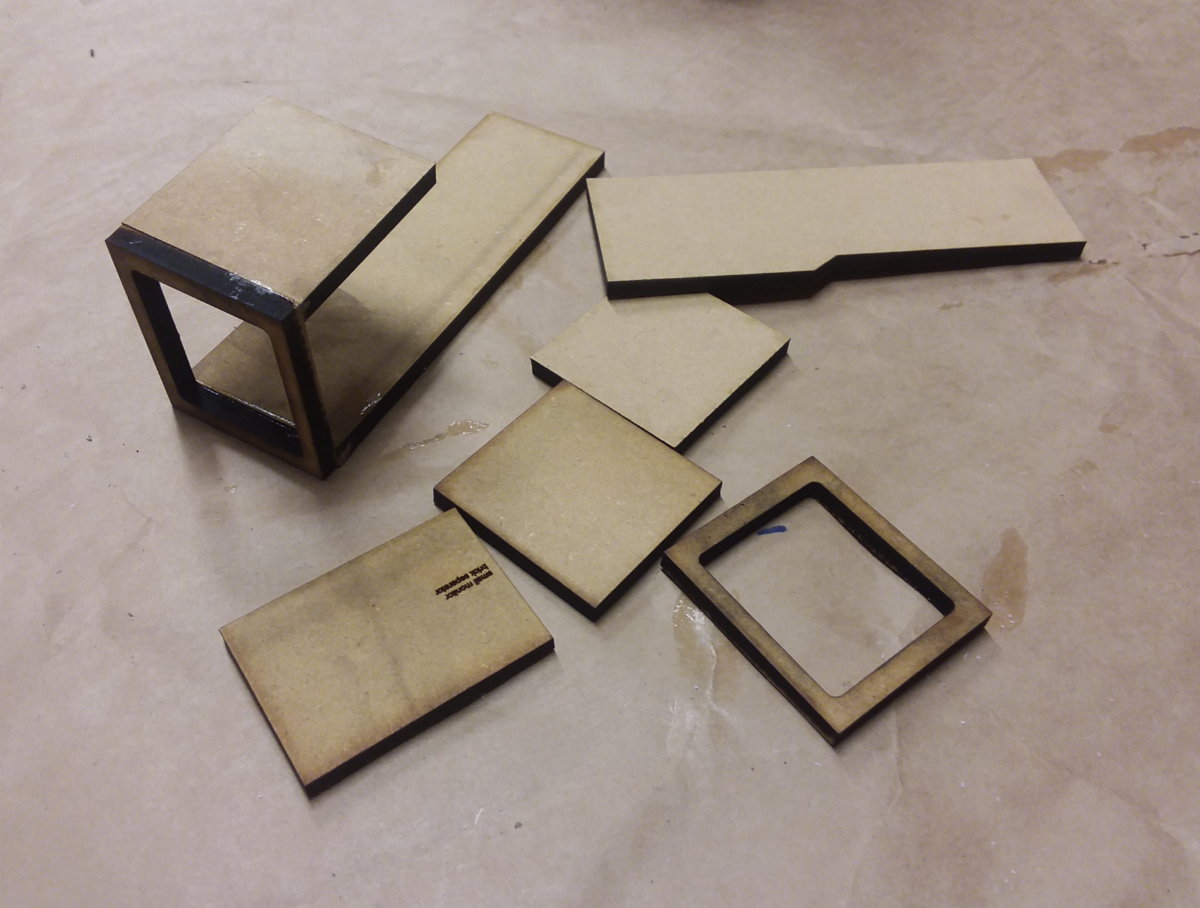

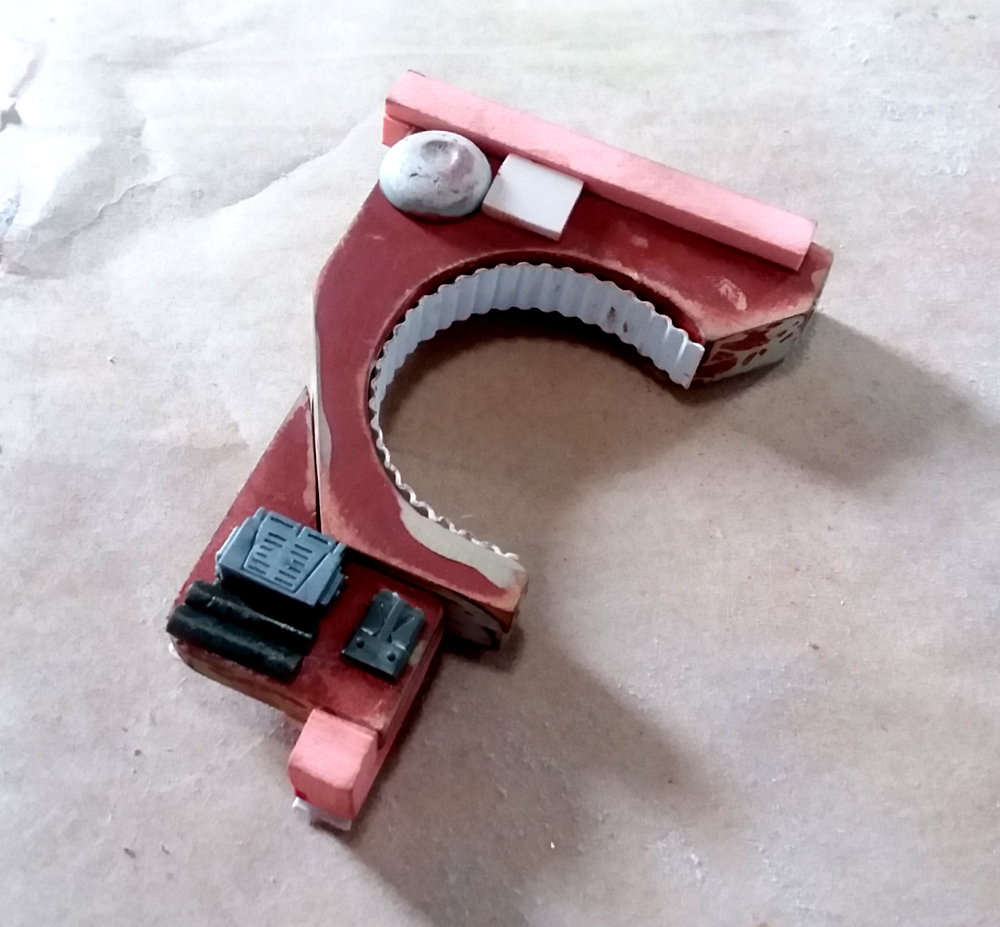

Here's a small example of how I approach a 3D shape in 2D. This is the eyepiece. Notice how I explode the levels so that they can be reassembled into the proper shapes from flat laser cut acrylic, styrene and mdf.

MAKING THE HERO MASTER PATTERNS:

I'm ready to laser cut the hero patterns with the knowledge I acquired from the throw-away model. Here we go............

Here's one of 4 full sheets of MDF and acrylic needed for the VK machine.

Developing the insets on the faceplate: During my drafting stage, I engineered recessed cutaways that will later be filled by separately cast components - primarily clear cast parts to allow for lighting features.

Sketching/blocking out the major shapes:

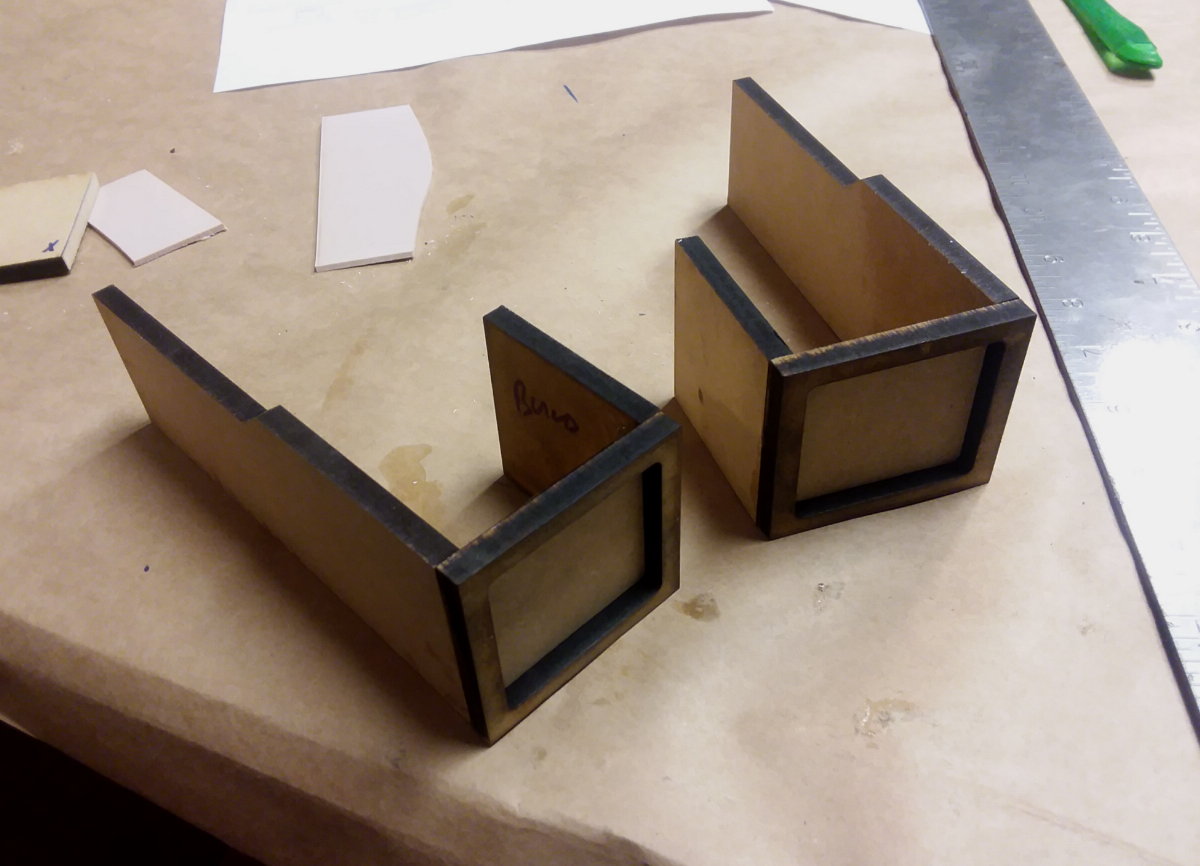

Here's the small monitors beginning assembly:

Blocking out the rear of the unit:

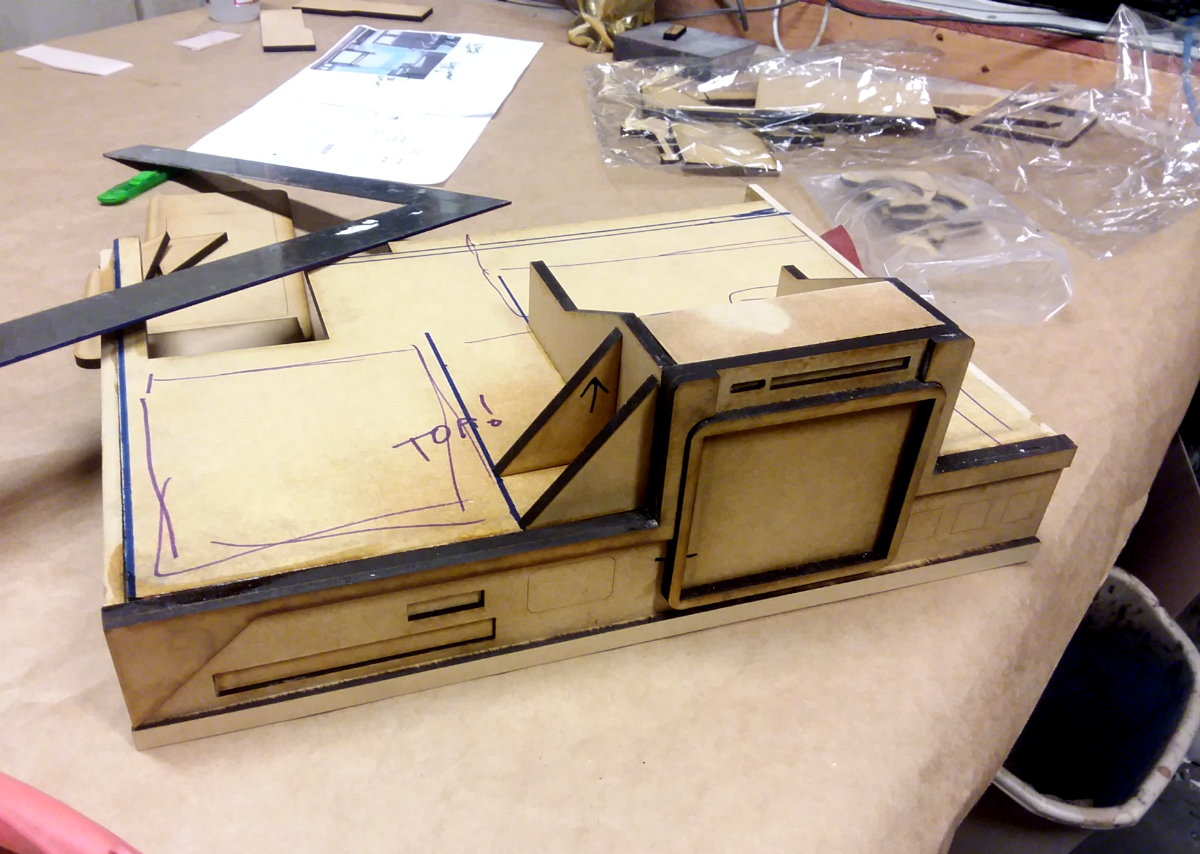

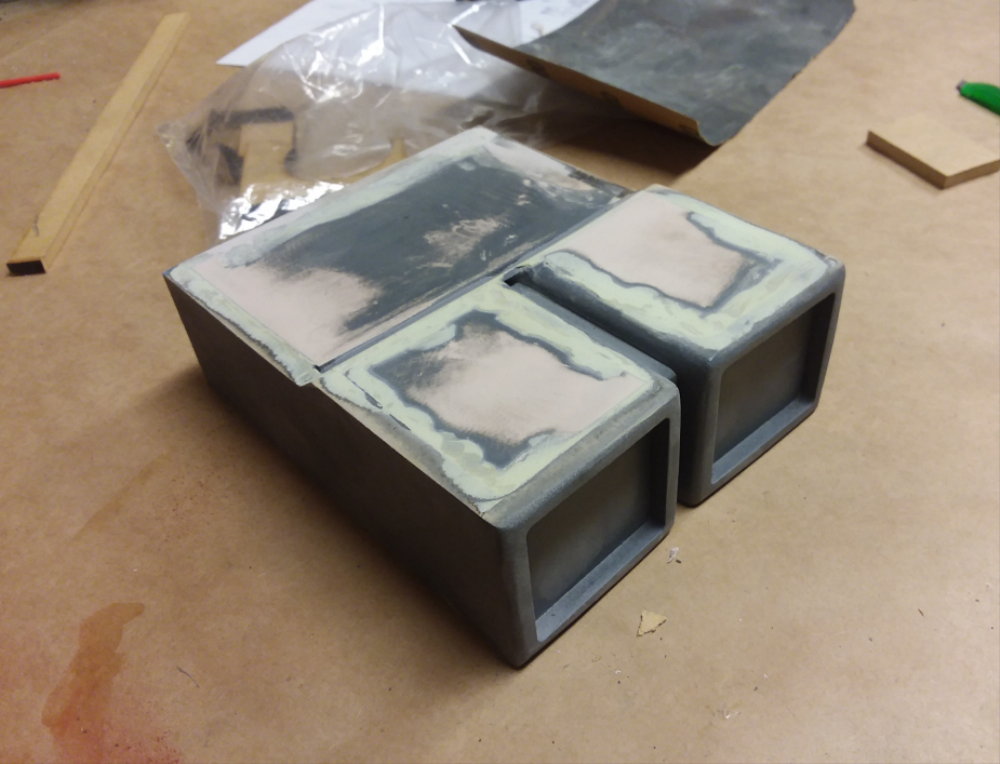

The sharp angles will soon be rounded over. By building the machine in real life (as opposed to drafting it digitally), I am learning it has a strong aesthetic of 'curviness'. Those sharp 90 degree angles are going to be softened up and angled in the coming days..

More development of the back section.

Styrene was added to start introducing slopes. I've begun applying fillers and am gearing up to start sanding. Dust, here we come.

Eyepiece development begins...

First piece ready for casting. I'm making an rtv mold to cast onyx positive bucks for vacuforming 4 shells.

Surgery time on the front left corner. It's a funny thing that happens when you build and hold something in your hands. You begin noticing small things that otherwise are very easy to overlook. A prime example of this is the left corner. After having the physical model, it became apparent that I missed an inset detail. I spent a few days hacking the corner apart to remodel that corner.

BELLOWS STACKED PROPERLY (horizontal slant made using spacers between each of the four bottom levels)

Developing the swing-arm:

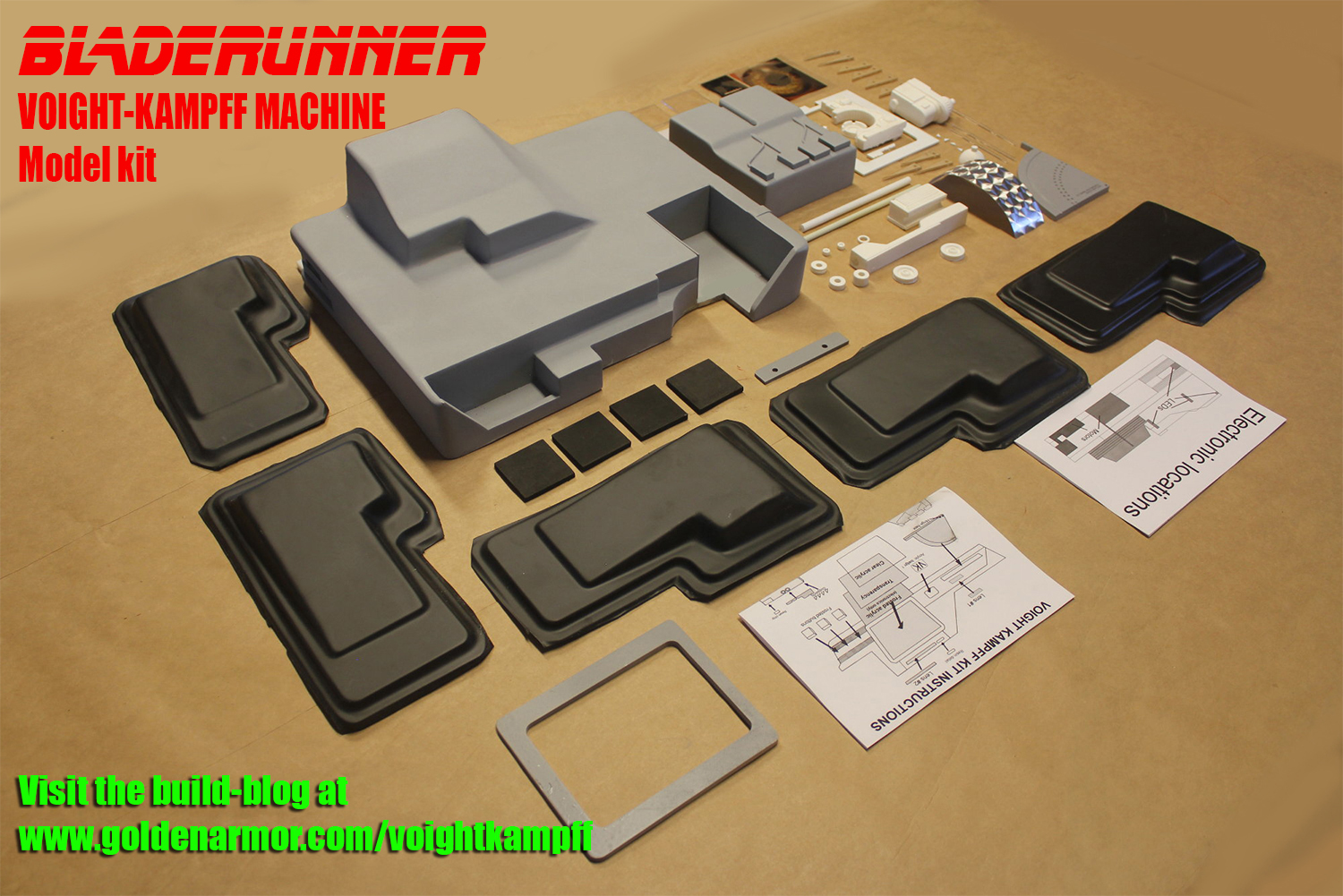

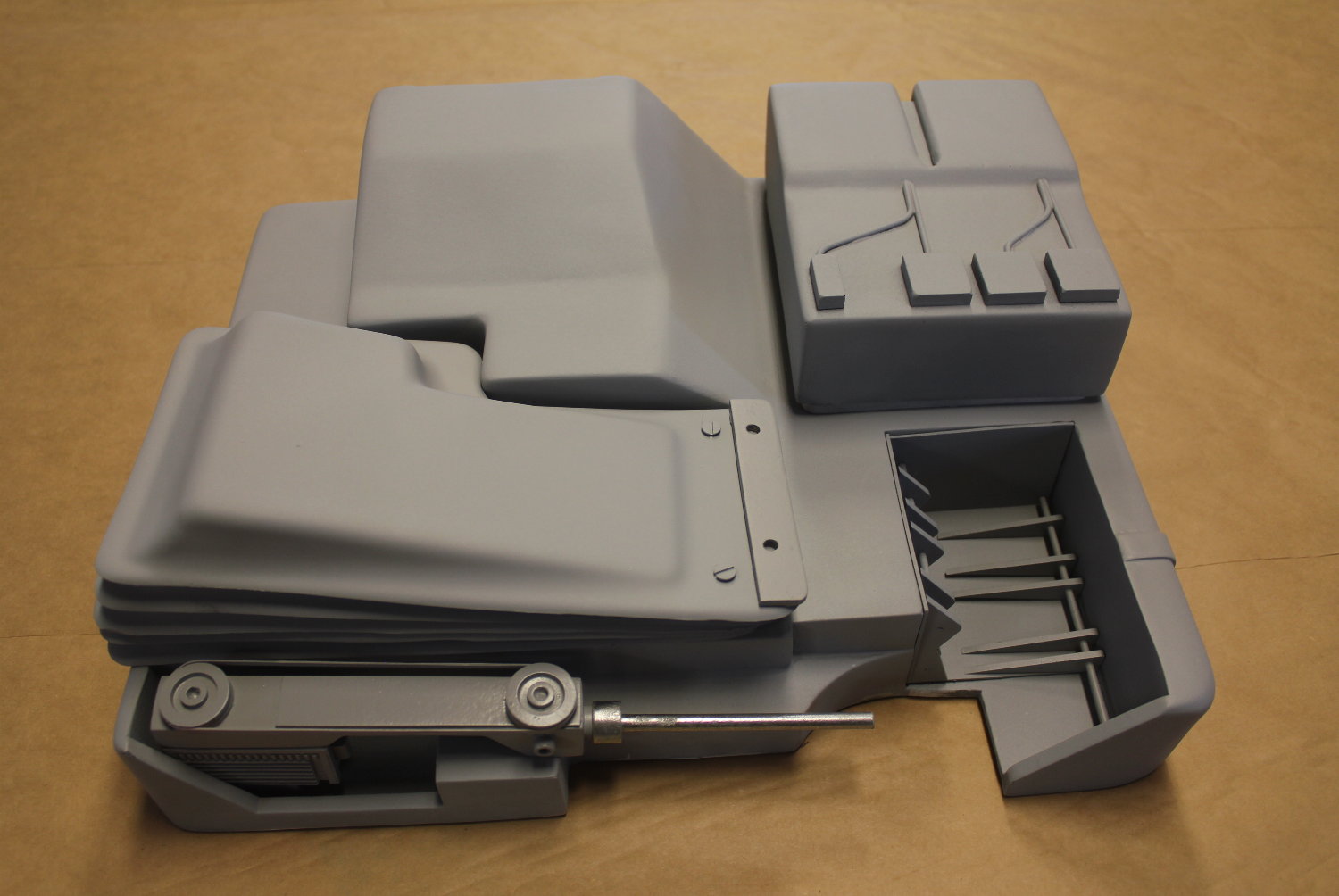

First set of test castings from the molds

LASER CUT BASE PADS (to be molded in rubber) and miscellaneous detail parts.

GRAPHICS

MATRIX MOLDING THE BODY!! THIS PROJECT IS A WRAP!

THE KIT IS COMPLETED! NOW THE FUN BEGINS.

THE FIRST STUNT BUILDUP OF THIS KIT: (no moving parts, no lights):

DEVELOPING 'BREATHING' BELLOWS:

I'm rethinking the color entirely. Most builders paint theirs grey with no color at all. Some still photos show it TOTALLY blue, and others show it just a tiny bit blue. On film it looks 100% grey. I like somewhere in the middle. I was doing some photoshop tests this morning and came up with these values:

R 78

G 92

B 120

OTHER BLADE RUNNER REPLICAS: