Fire & Ice Custom Fabrication

DreamScheme Studios was recruited in 2011 to design and create the three main hero characters for FIRE & ICE, a magnificent live stage show production which is also the basis for a film and video game. The producers were preparing to take the show nationally and required updated and improved charcters (helmets, weapons, suits of armor) to take the production level up several notches.

Below are several photos showing the production of these helmet and armor sets. The design and fabrcation team consisted of: Rod Ford, Chuck Westfield, Cristofer Adrian, with additional help from Julie and Nancy Goodson, Joseph Bosse and Max Ford.

We were commisioned to create THREE separate characters: GHOST, SHINE, AND BLAZE.

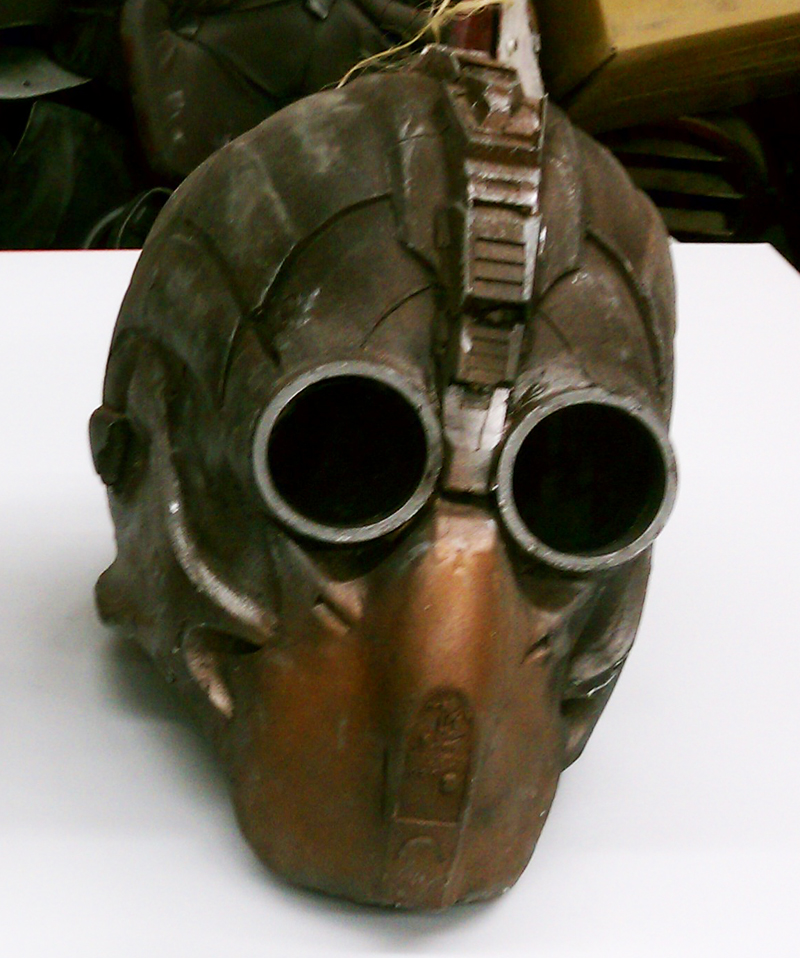

SHINE

The character of SHINE is meant to be a Steampunk aesthetic combined with a swashbuckler (aka Han Solo) style. He was to have a flight-mask breather on his face. The rest was up to us:

Once the sculpt was completed, our team created an RTV rubber mold to allow a urethane and rubber urethane moulding reproductions.

Using the urethane resin prototype casting, we toyed with the idea of giving him leather accents, but later decided to keep the helmet bare.

Final design and color pallete for Shine.

Once the color scheme was determined, a rubberized urethane casting of the helmet was made, detailed, and painted. Then it was lined in foam and lenses installed. The rubberized urethane proved to be a tricky format, but in the end it produced a helmet that is indestructable and easily reproduceable.

A shoulder and shins were then fabricated from thermal formed plastics. The emblem on Shine's shoulder represents his race and status.

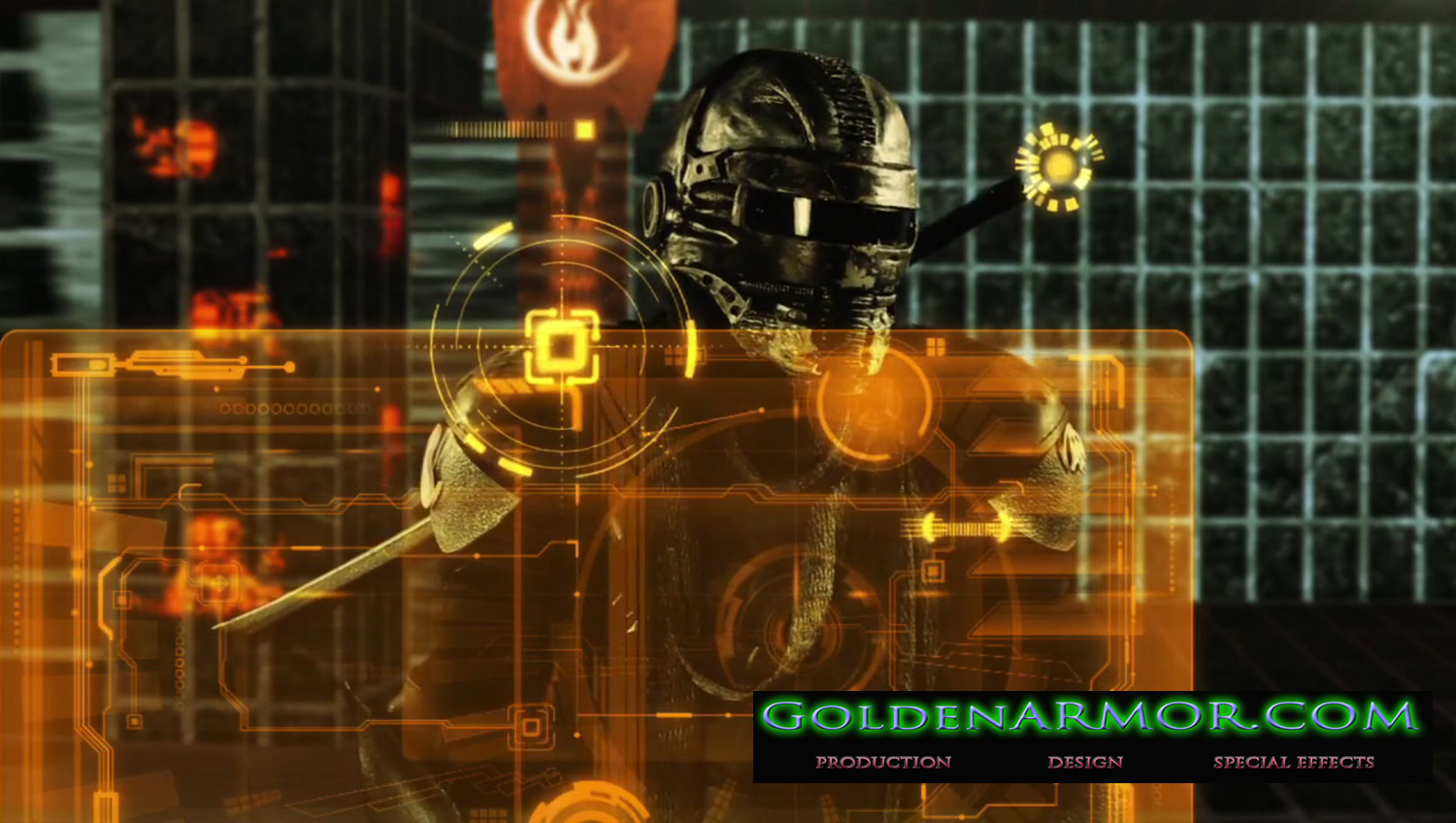

GHOST

In the producer's notes, Ghost is described as a cross between a grim repear a a ninja, fast and sleek, with elements of batman and Halo-esque design aesthetics.

Here's the intial sculpt in progress.

The helmet went through a hard plastic resin prototype phase before becoming a rubberized urethane final helmet (unbreakable). The visor and helmet liner were installed and the helmet fully painted.

The body armor was created as a flexible, articulated armored suit.

Like the other characters, GHOST has custom laser cut insignias of his race on his right shoulder, left shoulder is his team designation.

BLAZE

Blaze was described as a cross between a classic Knight and Optimus Prime, with futuristic elements of a War-hammer style warrior. This was to be the central character, LARGE and Impressive. He was, by far, the most difficult to fabricate from scratch.

Noel helping with the molding stage.

Shoulders in progress. I kept directing Chuck to make the BIGGER ever half hour. These shoulders determined the final size of the chestplate and other body parts.

Max is hellping produce the foam sculpting armature for creating massive shin armor.

What you see in the photo below is the urethane mold negative for the kneeguard and the foam armature for the shins (before clay was sheathed over the surface).

This is the shin guard with a layer of sculpted clay. This is our prototype which we eventually simplified into a buck to produce thermal formed duplicates (lighter and easier to wear than our initial rubber versions).

The forearms were sclupted in clay, and molded to producea flexible, durable, wearable armor.

You can see the BOOT that was sculpted for blaze in this shot, along with the shin and arm molds in progress.

Nancy working on the mothermolds for Blaze's body parts.

The chestplate for blaze was created from scratch using the same techniques shown above.

Chuck and Rod de-molding the chestplate mold.

This shows our first version of the shoulder bells, which were cast rubber urethane. They were heavy and clumsy which led us to create an internal armature. We eventually abondonned the rubber version of the shoulders and opted for thermal formed shoulder bells which were a fraction of the weight but equally strong when utilizing the identical armature system.

This belt buckle was first draw as a vector file in CAD software, then laser cut in 1/4" acrylic, molded, then positive flexible parts were made, painted, and assembled.

Our suit was shipped to the production team for final assembly onto the soft suit components they had prepared separately. In these test shots, Blaze is missing his cape,his undersuit, gloves, buckle, skirt covering, weapons etc...Final pics COMING SOON!!!