CUSTOM MOVIE SCI FI ARMOR

At DreamScheme studios, we are more than happy to discuss your custom projects. We are fully equiped costume and prop shop, servicing the industry for over 18 years.

For the independent Sci Fi movie, CARGO, we were tasked with building two of the characters from scratch. Here's how it all came together.

Here's how it was all made:

SHOULDERS/SHINS/ARMS

The various non flexible armor parts were sculpted as clay forms with the eventual goal of converting the sculpts into thermal forming bucks. The clay sculpts were thermal formed once, the negative spaces were cast in stone, smoothed, and finally the master patterns were thermal formed once again, trimmed, sectioned, and finally re-assembled.

Here you can see the thermal formed shells. Each armor piece is double-layered. The upper-most layer is sectioned into 3 parts and assembled onto the base form to create the specific aesthetic. We counted over 4 dozen parts were created that serviced only 2 character suits. That's a lot of parts!!

To achieve the chromed look, the parts required an automotive lacquer and enamel gloss coat. The silvering was accomplished using ALCLAD.

CHESTARMOR:

We started with a design change. The filmmakers wanted more of a JUDGE DREDD style chest that looked like leather. I decided to cast VITAFLEX 40 armored chestplates. The result would be like a flexible tire rubber, and have the leather-looking appearance the director wanted.

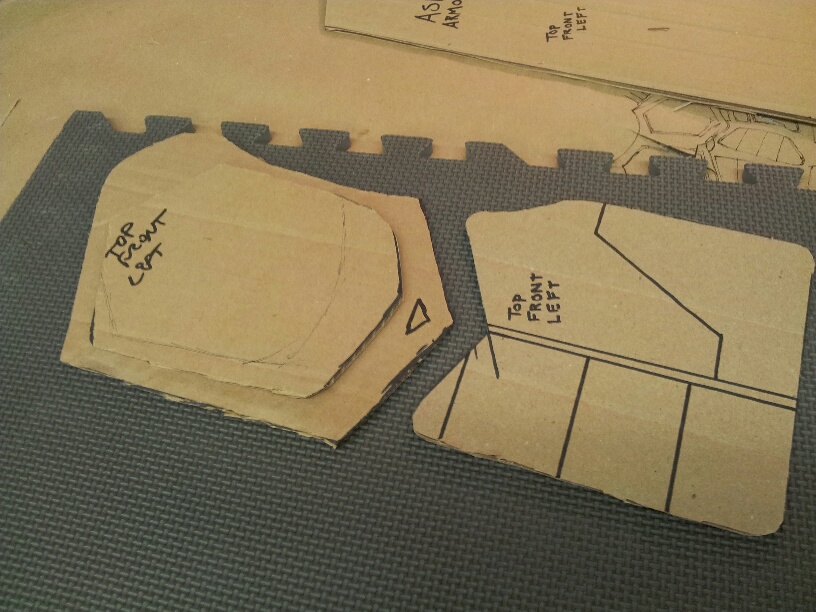

First we drew out some chest armor ideas, drew them out onto cardboard templates, then cut the base patterns from EVA foam.

One layer at a time, the armored chest was created by shaping and stacking foam.

The process is time-consuming, but after a few nights the pattern really started taking shape.

After a little more smoothing, final smooth and molding:

Once the pattern was completed, it was molded using silicone rubber and a plaster mothermold. Two castings were then made using a flexible urethane compound. This resulted in a chestarmor that was firm, yet flexible to the wearer. 1" webbing was secured in each corner to allow the costume director to assemble the suits to each actor.

HELMET

Here's how the helmet was made:

This project had a RAPID DEADLINE delivery window (4 weeks) so decided to take an existing sports helmet and modify it to fit our needs. In this instance, we started with a hocky helmet and designed outer panels to give it that sci fi look. The visors were then tinted black and the panels painted in the ALCLAD process.

PAGE IN PROGRESS JULY 2015

pwidth: 1000px;

/pp style=